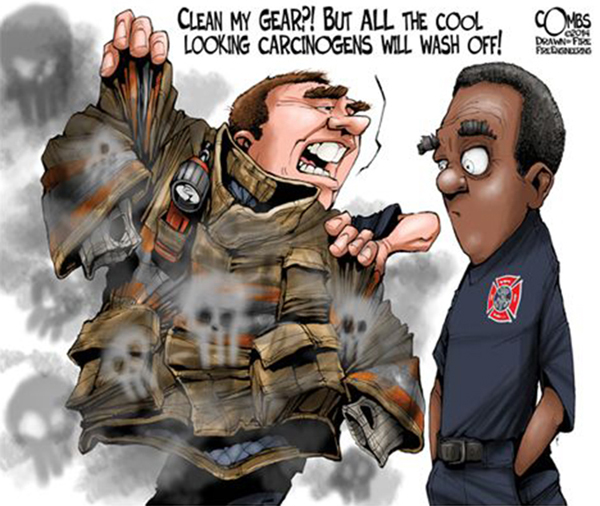

In 2014, NFPA 1851 was established to set requirements for the proper selection, care, and maintenance of firefighting protective gear to reduce health and safety risks associated with improper maintenance, contamination, or damage. Sections 6.1 through 10.1.1 detail procedures for inspecting, cleaning, repair, storage and eventual retirement of PPE. While these regulations are clear and to the point, sometimes firehouse culture and traditions can get in the way of common sense safety.

The days of being a “smoke eater” fighting a fire without SCBA are long gone and for good reason; breathing in smoke is inherently bad for you. The same is true of wearing soiled PPE. It’s not a badge of honor or courage—it’s a serious health risk. Multiple studies have found that soiled PPE can be impregnated with an extremely dangerous cocktail of hazardous chemicals and known carcinogens. Studies by the American Society of Testing Materials (ASTM) have also determined that accumulated soot on PPE can:

- Diminish its ability to reflect radiant heat.

- Make it increasingly ignitable.

- Reduce its ability to repel water.

- Increase its electrical conductivity.

- Weaken the fabric making it susceptible tears and punctures.

Clearly, the case for clean gear is settled, so the best thing you can do is to carefully follow the regulations set forth in NFPA 1851. Adhering to them will help to protect you from exposure to harmful contaminants and known carcinogens which may be present on your gear after use. In doing so, you will also have the added benefit of extending the service life of your equipment.

Whose job is it? It depends on the level of soiling. A key thing to understand is how NFPA 1851 details a department’s responsibilities:

- 7.1.1: Organizations shall provide a means for having ensemble elements cleaned and decontaminated.

You must understand, however, that PPE is PERSONAL and it is your life on the line. To that end, NFPA 1851 states:

- 7.2.1: The end users shall be responsible for the routine cleaning of their issued ensemble and ensemble elements.

Routine cleaning is defined as simple brushing to remove dry debris, rinsing with a water hose, and spot cleaning with a soft bristle brush. Should the PPE be heavily soiled, sections 7.2.2 through 7.3.1.1 offer guidance for advanced cleaning, which must be done by a verified Independent Service Provider (ISP) or trained department personnel:

- 7.2.2: Organizations shall examine the manufacturer’s label and user information for instructions on cleaning and drying that the manufacturer provided with the ensemble or ensemble element. In the absence of manufacturer’s instructions or manufacturer’s approval of alternative procedures for the ensemble or ensemble element, the routine cleaning and drying procedures provided in this section shall be used.

- 7.3.1: Advanced cleaning shall be performed by a verified ISP or the organization’s trained personnel.

- 7.3.1.1 The advanced cleaning shall be managed by a member of the organization or conducted by members of the organization who have received training in the advanced cleaning of protective ensembles and ensemble elements. The ensemble or ensemble element manufacturer and the organization shall determine the level of training required to perform advanced cleaning. The ensemble or ensemble element manufacturer shall provide written verification of training.

Advanced cleaning is typically carried out in a commercial front-loading washing machine or extractor. Follow all the garment manufacturer’s laundering guidelines. Heavily soiled areas should be pretreated. Separate shells and liners, remove suspenders, and fasten all closures to prevent damage while washing. Gear can either be air dried or mechanically dried, which includes traditional tumble dry style and newer drying cabinets. Some PPE manufacturers specify drying cabinets with factory preset temperatures for their brands incorporating the latest technology materials, so it is advisable to check with your manufacturer.

Once the gear is properly cleaned and dried, repairs (if necessary) should only be performed by the original manufacturer, an ISP, or a department member who has been fully trained by the manufacturer or ISP.

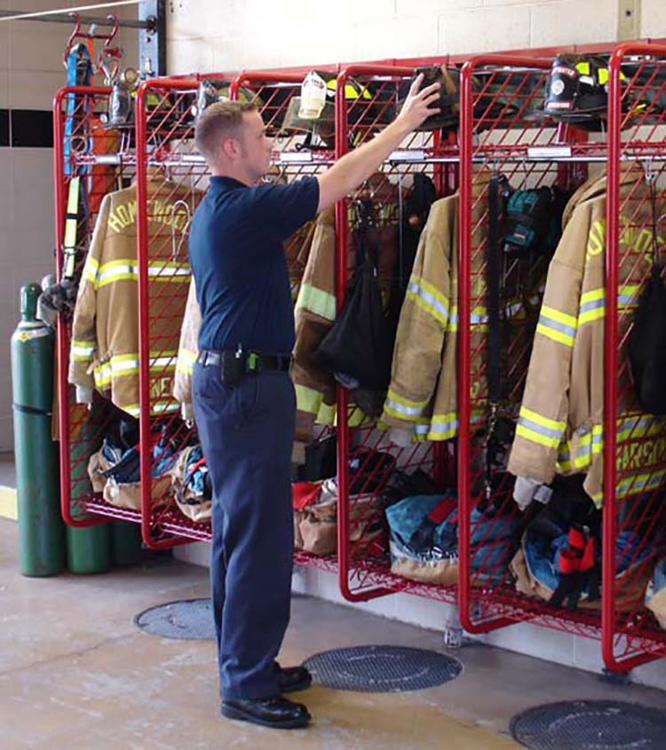

Store decontaminated PPE by hanging in a clean, dry, and well ventilated area that does not expose it to direct sunlight to avoid degradation from ultraviolet (UV) rays. Prolonged exposure to UV rays will accelerate the aging process and diminish the protective properties of the fabrics. Hanging coats and trousers will prevent damage caused by creasing or folding and allow them to air dry if merely damp from routine cleaning.

Following proper cleaning, drying, maintenance and storage protocols will help to protect you from exposure to harmful toxins. It is your personal responsibility to make sure that your PPE receives routine cleaning after every call and that it gets advanced cleaning when necessary from trained personnel. Robert Gilbertson, national sales manager at Veridian Fire Protective Gear sums it up succinctly:

Dirty PPE is a health risk.

- Inspect it as required.

- Clean it correctly.

Provide clean, dry, and well ventilated storage areas.

- Provide dedicated space away from living areas and out of apparatus bays.

- Provide appropriate gear racks.

Control exposure to light.

- Be aware of windows and openings.

- DO NOT STORE PPE IN DIRECT SUNLIGHT.

Minimize personnel and the public exposure to soiled or contaminated PPE.

- Do not wear or store PPE in living areas.

- Do not take soiled or contaminated PPE home.

NFPA 1851 is a common sense set of requirements designed to help you and your department reduce risks of on scene injuries and long-term illnesses caused by exposure to known carcinogens. These protocols simply must be performed after every call. Don’t think of them as cutting into your downtime, think of them as extending your LIFETIME.

Groves Incorporated manufactures Ready Rack and a complete line of PPE care equipment. More information is available at www.readyrack.com.