By Robert Tutterow

Earlier this year, Chief Bobby Halton, FDIC education director and editor in chief of this magazine and Fire Engineering, was passionate about firefighter fatigues.

He thinks they should be worn for all our calls except structural fires and hazmat incidents. To illustrate his passion, fatigues were worn by all 130 hands-on training instructors at FDIC International 2016. It is important to understand that when referring to fatigues, the reference is not about cargo pants for station wear. It is about a set of personal protective equipment (PPE).

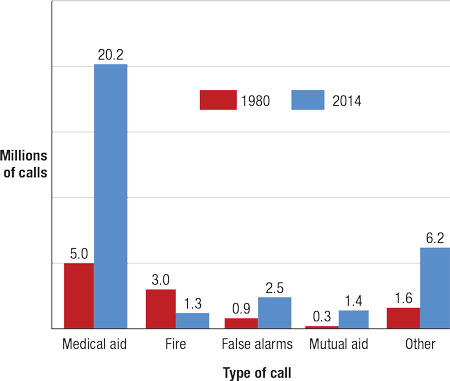

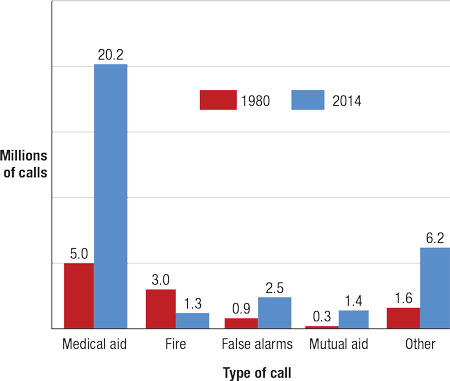

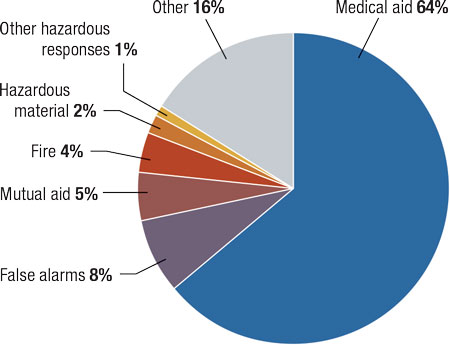

The types of calls and the percentages for each type are changing. When viewed over the past 30 or more years, the change has been drastic. Refer to Figures 1 and 2 above. Based on the changing responses, the idea of fatigues seems to be a “no-brainer.”

Background and Drawbacks

No discussion about firefighter fatigues would be complete without acknowledging the TECGEN® brand. TECGEN first entered the fire service market in 2009. In 2015, it was acquired by Fire-Dex. TECGEN saw an obvious need for firefighter PPE other than structural firefighting PPE. The product has experienced slow and steady growth. Perhaps that growth will accelerate with strong advocates such as Chief Halton. This will be validated as we start to see other manufacturers offer firefighter fatigues.

If fire service fatigues are such a “no-brainer,” why has the concept seen slow adaptation? First of all, cost. Any piece of expensive equipment, especially when needed for each firefighter, has an uphill battle. If the item has not been a traditional part of a line-item budget for a fire department, it faces even more difficulty. However, on further review, there are cost benefits. UV degradation of turnout gear is reduced, and the need to repair turnout gear is reduced since it is not used as often. And, the cost of repairing fatigues is significantly less than for structural firefighting gear.

|

| Figure 1: Comparison of Fire Department Calls in 1980 and 2014. Reprinted with permission from NFPA’s report, “Fire Loss in the United States During 2014,” by Hylton J.G. Haynes, Copyright © 2015, National Fire Protection Association. |

TECGEN uses a unique fiber for its garments that is not found in structural firefighting outer shells. The fiber has an elastic core surrounded by a carbon shell for added flexibility, durability, and breathability. The material in the TECGEN fabric is extremely durable with 35 pounds of tear resistance and about 225 pounds of breaking strength. National Fire Protection Association (NFPA) 1951, Standard on Protective Ensembles for Technical Rescue Incidents, requires 6.75 pounds and 90 pounds, respectively.

Another difficulty is the logistics of managing fatigues. Combined with structural gear and often wildland firefighting gear, where are fatigues stored? Locker space is already at a premium in most fire stations, and apparatus cabs are already too tight and crowded. However, with some creativity, logistics issues can be overcome. The dual certification to NFPA 1951 and NFPA 1977, Standard on Protective Clothing and Equipment for Wildland Fire Fighting, helps with many fire departments. And, some fire departments have taken the approach of fatigues as their “second set of gear” since more than 90 percent of their responses are nonstructural. As the fire service starts to understand the benefits, the cost factor should be easier to substantiate.

Benefits

The benefits of fatigues are numerous. For about 90 percent of fire department responses, fatigues provide a lighter weight, more maneuverable level of protection. Fatigues are suitable for extrication, motor vehicle accidents, forest fires, grass fires, brush fires, high and low angle rescue, search and rescue, certain public appearances, and goodwill calls. Some departments have found them to be great “identity” garments for their explorer or junior firefighter programs.

|

| Figure 2: Fire Department Calls in 2014. Reprinted with permission from NFPA’s report, “Fire Loss in the United States During 2014,” by Hylton J.G. Haynes, Copyright © 2015, National Fire Protection Association. |

Health benefits

It is common that firefighters responding to nonfire events wear contaminated structural PPE-especially the helmet, coat, pants, and boots. Structural gear is the default “ensemble” of choice when something other than station work uniforms is needed. These responses often expose patients to contaminants.

More critically, when TECGEN® first entered the fire service market seven years ago, cancer awareness was barely on the radar. Since then, it has become the focal point in firefighter health. As firefighters continue to wear structural gear (shall we say-needlessly?), then firefighter exposure to carcinogens is not being minimized as it should. In a properly managed program, firefighter fatigues can be a giant leap in reducing exposure to contaminated gear. This is especially true if structural gear is kept as isolated as possible.

With significantly less weight and increased breathability, fatigues reduce health hazards such as heat stress and cardiovascular risks. This leads to increased firefighter productivity when rendering service to the public. I remember an extrication incident on a hot summer day when additional units had to be called to relieve firefighters who were going down because of heat exhaustion. They were wearing structural firefighting PPE. Had they been wearing fatigues, there is no doubt they could have completed the task in a shorter time, provided much better customer service, not put their personal health at risk, and kept other companies in service. As the number of working fires continues to decline and the number of other types of emergency services continues to increase, the idea of fatigues makes more and more sense.

ROBERT TUTTEROW retired as safety coordinator for the Charlotte (NC) Fire Department and is a member of the Fire Apparatus & Emergency Equipment editorial advisory board. His 34-year career includes 10 as a volunteer. He has been very active in the National Fire Protection Association through service on the Fire Service Section Executive Board and technical committees involved with safety, apparatus, and personal protective equipment. He is a founding member and president of the Fire Industry Education Resource Organization (F.I.E.R.O.).