Alan M. Petrillo

Ultra high pressure (UHP)-is it the future of firefighting or will it be relegated to a few specialized areas of firefighting operations? That’s what I asked the makers of UHP pumps and equipment, and I found an array of opinions about the advantages and disadvantages of UHP and its uses.

Potential Applications

Steve Toren, director of North American sales and marketing for Waterous, says firefighting pumps can be ranked in three categories: low pressure, high pressure (HP), and UHP. “Low pressure under 500 pounds per square inch (psi) is standard for an NFPA 1901-rated vehicle,” Toren says. “From 500 to 1,000 psi, you get into high pressure, which is common in European applications where they run high- and low-pressure pumps simultaneously. Over 1,000 psi is considered UHP.”

Bill Carroll, general manager of HMA Fire, says his company considers ultra high pressure to be any pressure at the nozzle at or above 1,100 psi. “You have to generate 1,400 psi at the pump to get that nozzle pressure,” Carroll says. “With ultra high pressure, you’re breaking the water down into smaller droplets, so you have more surface area that allows you to suppress the fire with less water. You’re using water more efficiently with ultra high pressure, with 90 percent or more of the water being used, compared with a typical low-pressure water flow, where about 90 percent of the water is not being used efficiently.”

In the United States, UHP use first gained a foothold in wildland applications, Toren says, and now has moved into the aircraft rescue and firefighting (ARFF) arena and in some structural applications.

|

| (1) A Hale 4 HPS UHP pump is shown installed on a KME wildland vehicle. (Photo courtesy of Hale Products.) |

“Thus far, I see UHP as an enhancement to the existing pump on a structural firefighting apparatus,” Toren says. “You could put the UHP package up in the dunnage area of a pumper but have to be careful of the size fire you fight with it. It does a pretty good job of handling a room-and-contents fire, but I would get nervous making it the main pump on any apparatus, with the exception of wildland, rapid intervention, and ARFF vehicles.”

Toren notes that with an ARFF vehicle, the firefighters are inside the vehicle and usually have no need to be outside to fight a fire. In wildland applications, some fires can be fought from inside the vehicle by using a UHP turret, he says. And in some structural instances, a firefighter might push a lance-type nozzle through a wall to use a UHP stream to extinguish a room fire. “But the firefighter is outside the room and is protected by a wall,” Toren observes.

Pumps and Appliances

Lance-style nozzles for UHP work are made by PyroLance, which makes a nozzle of the same name that shoots a UHP stream of water together with a granite abrasive to pierce through all types of barriers. It also makes the PyroBlitz, a lightweight attack line nozzle, suitable for use on both structural and wildland fires.

Elkhart Brass makes the Sidewinder EXM UHP water monitor used widely on wildland attack vehicles; Task Force Tips (TFT) offers its BlitzFire package for wildland use; and Akron Brass offers the 3450, a UPH bumper turret that puts out 60 gallons per minute (gpm) at 1,100 psi.

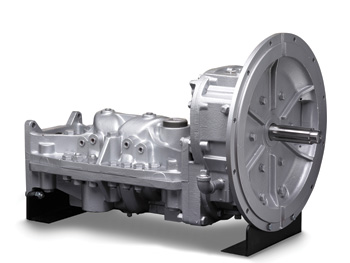

Waterous makes a UHP four-stage centrifugal pump, the CPT-4UH, that has been used on the United States Air Force’s P-34 ARFF rapid intervention vehicle. The CPT-4UH puts out 90 gpm at 1,350 psi, for a nozzle pressure of approximately 1,250 psi.

|

| (2) The Hale Products subsidiary in the United Kingdom, Godiva, makes the Prima, a multistage high- pressure and UHP vehicle-mounted pump. (Photo courtesy of Hale Products.) |

Toren says Waterous is developing another UHP pump rated at 200 gpm at 1,500 psi and expects it to be available in the second quarter of 2013.

Jason Darley, of W.S. Darley & Co., says his company makes a UHP centrifugal multistage pump for ARFF use that can flow 300 gpm at 1,300 psi. “We’ve been working with the military on this pump and have delivered prototypes for testing and approval,” Darley says. “And depending on the application, the pump can deliver up to 1,500 psi.”

Darley also makes the Darley U4 UHP pump that delivers 60 gpm at 1,000 psi, typically used in wildland and some fire attack applications, Darley says. “The high-pressure and ultra high pressure trend has come back around after 30 years or more,” Darley notes. “Perhaps it’s gaining some popularity here because of an influx from Europe where UHP and compressed air foam systems (CAFS) are common. There’s been some military testing with UHP that’s worked its way into the ARFF arena. Also, new people want to try new things and are always looking for a better way to do things.”

Carroll says that a typical HMA Fire UHP pump on a skid unit or utility terrain vehicle (UTV) puts out 20 gpm with 1,200 psi at the nozzle. HMA Fire also makes 10- and 90-gpm UHP systems. “Most of our skid units are being used in wildland applications,” he says. “The 90-gpm units are more for ARFF airport applications. We recently built a UHP and dry chemical ARFF unit to go on a Ford F-550 chassis for the United States Navy. It ordered three new vehicles and had us rebuild two others to those specs.”

|

| (3) Waterous manufactures the CPT-4UH, a four-stage UHP centrifugal pump that puts out 90 gpm at 1,350 psi. (Photo courtesy of Waterous.) |

A Method Without a Standard

Carroll points out that National Fire Protection Association (NFPA) standards do not address the issue of UHP, only the gallonage needed to go into and attack a structure fire. “Ultra high pressure doesn’t meet the gpm to go into a structure fire,” he says, “but for a single- room fire, UHP is such a quick responder that it’s able to stop a fire before it gets bigger, knowing that a fire doubles about every 30 seconds.”

Carroll notes that the Fire Apparatus Manufacturers’ Association’s (FAMA) Plumbing Technology Committee is in the process of developing a definition for UHP that could be used by the NFPA.

UHP Has Its Place

“UHP is not the end of it all,” Carroll says. “If you have a fully involved structure, UHP won’t put the fire out. It doesn’t replace the low-pressure way of putting out fires, but it’s an enhancement. It’s a great tool to have on a fire truck.”

Dominic Colletti, chief brand marketing manager for Hale Products, says Hale’s subsidiary, Godiva in the United Kingdom, produces the Prima, a multistage high-pressure and UHP vehicle-mounted pump. “We recently took our UHP pump to Tyndall Air Force Base’s research lab and tested the pump on JP-8 flammable liquid and came up with very good results in extinguishing it,” Colletti says. “We presented our findings to the FAMA Technical Committee.”

|

| (4) HMA Fire recently furnished the United States Navy with utility terrain vehicles (UTVs), mounting UHP skid units that can put out 20 gpm with 1,200 psi at the nozzle. (Photos courtesy of HMA Fire.) |

Colletti points out the United States Air Force recently awarded a contract for rapid intervention vehicles that use UHP as the water delivery method instead of low-pressure pumps or CAFS.

However, Colletti is skeptical about the use of UHP for typical structural firefighting. “In a free burning or ventilation-limited fire, a volume of water is what puts the fire out, whether it’s delivered at low pressure, high pressure, UHP, or [with] CAFS,” he says.

Colletti notes, “You can take a UHP line and hold a room-and-contents fire in check, but when we go to structure fires, we want a safety net regarding the flow rate, which is where a higher flow rate is superior. The extra delivery rate of gpm is what puts out a fire that’s extending.”

He continues, “UHP has its place, but it’s not everywhere. The fuel load in a fire reduces to the critical application rate of the suppression agent, so the structure burns down to the amount of water you’re putting on it.”

|

| (5) A firefighter uses an HMA Fire UHP on a UTV to fight a wildland fire. (Photo courtesy of HMA Fire.) |

ALAN M. PETRILLO is a Tucson, Arizona-based freelance writer and is a member of the Fire Apparatus & Emergency Equipment editorial advisory board. He served 22 years with the Verdoy (NY) Fire Department, including in the position of chief.