The trend toward carrying as much water as possible on a fire apparatus means there must be efficient methods of filling water tanks and getting the water out of them.

Tankers and pumper-tankers each have their own typical arrangement of intakes and discharges, but some fire departments are asking manufacturers to be creative when locating both dump valves and intakes.

Discharge Types

Greg Lewis, inside sales manager for Spartan ER, says his company has built a tanker with a 16-inch dump valve for Hillsborough County (FL) Fire and Rescue. “It was an unusual installation,” Lewis says. “It was a large air-operated butterfly valve that went on the rear of a 3,500-gallon elliptical tanker. The fire department was able to get a 3,100-gallon-per-minute (gpm) flow out of it.” He adds that when the mission is pure water handling, whether on a single- or tandem-axle tanker, one dump at the rear of a wetside tanker where the tank is outside of the body allows Spartan ER to lower the center of gravity of the truck and lower the cost too.

Ryan Slane, pumper-tanker product manager for KME, notes that “the latest trend is a single rear dump with a 180-degree swivel that’s integral with the water tank. It’s one dump, which means less body work, less weight, and less cost of two additional side dumps.”

|

| 1 Pierce Manufacturing Inc. installed a 10-inch round side dump on each side of this tanker built for a South American fire department, along with a 10-inch rear dump. (Photo courtesy of Pierce Manufacturing Inc.) |

David Stock of A.H. Stock Manufacturing, says his company makes the Newton Kiwk-Dump Valve, named for the town where it was invented. “Our 1010 plunger-style valve will flow 2,940 gpm, while our 1050 model, where the plunger flips straight up into the water tank, will flow up to 3,570 gpm,” Stock says.

A.H. Stock makes the Newton Kwik-Dump Valve in both steel and stainless steel models, although Stock notes that nearly 70 percent of those sold are stainless steel. A.H. Stock also makes an extend-a-chute and a swivel chute that allow water to be dumped over a 180-degree arc. “Our telescoping chute extends 36 inches, and we also have a slip-on chute that gets attached manually,” he says. “We offer both electric and air operation for our chutes and valves, although it’s almost 99 percent electric on the valves now.”

David Durstine, vice president of marketing for Akron Brass Co., points out that Akron Brass has one product that can be used as a dump valve. “It’s an eight-inch round butterfly valve that can be built for manual, air actuation, or electric operation,” he says. “The most versatile is electric operation because it allows more finite control of the valve, while with air, it is either open or closed.” The butterfly valve is available in sizes from four to eight inches around.

|

| 2 This jet dump valve was installed at the back of this tanker for a Canadian fire department by Fort Garry Fire Trucks. A jet dump uses the venturi effect to increase the flow of water from a dump valve. (Photo courtesy of Fort Garry Fire Trucks.) |

Steve Suche, government and export sales manager for Fort Garry Fire Trucks, says for one customer it installed a Jet Dump, a five-inch dump chute that uses the venturi effect to increase the flow from a dump valve. Jet dumps can be either internal or external to the water tank, although internal valves are most commonly found on tankers.

Dump Valve Operation

Clarence Grady, application manager for fire suppression and foam systems at Pierce Manufacturing Inc., points out that dump valves can be operated in one of three ways: manually by means of a lever or hand crank, electrically, or air actuated. “Manual round dumps are typically large butterfly valves, and we recommend a gear-operated hand crank for them,” Grady says. “The most popular dump valve we install is the electric-over-air actuating valve, where the controls in the cab have one switch for the valve and one for the valve extension. The electric switches operate a small electric valve that pilots the air cylinder to open the butterfly or the chute, whichever is chosen.”

|

| 3 The Kenley (NC) Volunteer Fire Department had Spartan ER build this 2,500-gallon elliptical tanker with two three-inch tank fill inlets and one 10-inch square Newton Kwik-Dump valve at the rear of the vehicle. (Photo courtesy of Spartan ER.) |

Suche says that while many tankers have three dump valves, one at the rear and one at the back of each side of the vehicle, they often are electrically operated, although air operation is more traditional. “Air operation is more economical and a little more durable than electric operation of dump valves,” Suche points out, “but the decision comes down to the fire department’s choice.”

Slane says KME offers round dump valves in eight- and 10-inch diameters and a 10-inch square dump valve, which Slane says gives greater flow and a higher dump rate. “We like to see fire departments go with electric dump valves, which can be stopped part way to reduce the flow of water,” Slane points out. “They are able to be opened slowly and feathered closed if necessary. With round dumps, they are only air operated, so they are either fully open or fully closed.”

|

| 4 KME put 10-inch Newton Kwik-Dump valves between the dual rear wheels on this tanker it built for Jersey Shore (PA) Independent Hose Company No. 1. (Photo courtesy of KME.) |

Joe Messmer, president of Summit Fire Apparatus, points out that many fire departments today are starving for personnel to staff their rigs. “Electric dump valves allow a vehicle to be a one-firefighter truck, whether it’s a tanker or a pumper with a large water tank,” he says.

Dump Valve Location

KME offers fire departments three locations for side dump valves. “We’ll put them forward of the rear axle, split in between tandem rear axles, or to the rear of the rear axle,” Slane says. “We often use side cameras so the operator can see any obstacles or if he is too close or far away from the portable tank. The camera can be triggered with the chute extension, or the master dump power, or for a manual turn-on.”

|

| 5 The Boothsville (WV) Volunteer Fire Department had Summit Fire Apparatus install a 10-inch square rear dump valve with a three-foot extension and two 2½-inch intakes on the back of its tanker. (Photo courtesy of Summit Fire Apparatus.) |

Grady points out that Pierce has built some tankers with front dump valves, although they are not the norm. “Between the tandem rear axle wheels is getting to be a popular place for side dumps on tankers,” he says. “They usually are electrically operated so the driver can offload without getting out of the cab as long as the water supply officer has arranged the portable water tanks well. The operator can drive up, dump the water, and drive away, which minimizes water dumping time.”

Grady says that in the past few years “a lot of work has gone into improving side dumping from tankers.” Pierce is installing both square and round dump valves, he notes, “but we’re doing more large round side dump valves in the eight-inch to 10-inch diameter size, as well as triple dumps, one at the rear and one on each side at the back of a vehicle.”

|

| 6 Summit Fire Apparatus put three 10-inch square dump valves on this tanker, one on each side behind the dual rear axles and one at the rear of the vehicle. (Photo courtesy of Summit Fire Apparatus.) |

Messmer says triple dump valves give the vehicle operator much more flexibility when off-loading water. “No one tanker operation is the same,” Messmer says. “The arrangement of the portable tanks can be different for each call, so it’s important for an operator to drive up and hit a portable tank without having to leave the road. Speed on the road is not the goal; it’s getting the water off the vehicle as quickly as possible.”

Intake Valves

For intake valves, Lewis notes that Spartan ER installs a lot of Fireman’s Friend valves in 2½-inch to five-inch sizes. “We get a lot of requests for them,” he adds.

Grant Spencer, general manager of Spencer Manufacturing, agrees that Fireman’s Friend inlet valves “have become pretty much standard for filling water tanks.” While most Fireman’s Friend valves can be found at the rear of fire vehicles, often two four-inch valves or one four-inch and one 2½-inch valve, Spencer says he also has installed them at the driver’s side pump panel and also as a side-mount on the officer’s side.

Parker Browne, a spokesman for Fireman’s Friend Engineering Inc., says the unit is a fill valve that requires very little pressure to open. “The valve is very safe and will not freeze in the winter because the valve itself is on the interior of the water tank,” Browne says. “A firefighter simply hooks up the inlet line, charges it, and when it is shut off, it bleeds itself into the tank and takes pressure off of the line.”

|

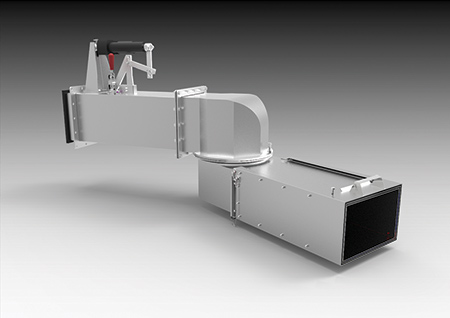

| 7 A.H. Stock Manufacturing makes several versions of the Newton Kwik-Dump valve, including this model 1070 gate-style valve with a swivel chute and telescopic extension attached. (Photo courtesy of A.H. Stock Manufacturing.) |

The Fireman’s Friend valves come in 2½-, three-, four-, and five-inch sizes and are tipped with either Storz or threaded fittings. They are spring-loaded so when the intake line is pressurized, the valve opens. But when the line is shut down, the spring loading closes the valve.

Summit Fire Apparatus likes to plumb intakes to the bottom of a water tank, then into another pipe that gets turned down at the top of the tank, Messmer says. “This keeps the back pressure from slowing down the fill rate,” he notes. “Two intakes is the norm on tankers and pumper-tankers-one at the bottom and another at the top. Three inches is a typical size that gets necked down to 2½ inches. The other type of intake is to fill the vehicle’s tank using large-diameter hose (LDH) through a six-inch butterfly valve intake.”

Pierce Manufacturing offers inlets that are manual, electric, and automatic electric direct tank fills, says Grady. “The smallest we offer is a 2½-inch, where fire departments usually install two of them, and the largest is a four-inch National Standard Thread, usually with a Storz fitting on it,” he notes.

|

| 8 Ashland-Grant (MI) Fire District had Spencer Manufacturing put a 10-inch square dump valve with an extension that rotates 180 degrees on the rear of its new tanker. (Photo courtesy of Spencer Manufacturing.) |

Doug Miller, OEM account manager for Task Force Tips (TFT), says TFT makes a number of valves that are used as intakes on tankers and pumpers. “Our ball intake valve is the most popular and often is used as a pump inlet valve and also for an LDH tank fill,” Miller says. “Tank fill valves usually run from four to six inches, while the smaller power takeoff pump on a tanker might take a four-inch intake valve.”

Often referred to as a ball intake valve (BIV), the larger pumper and tanker units typically have a five- to six-inch BIV with a wheel or crank handle, Miller points out. “We make an electric remote unit as well.”

Eric Combs, marketing manager for Elkhart Brass Company, says Elkhart Brass has three categories of intake valves: piston, ball, and butterfly. “The piston intake valve has been around for many years and is a tried-and-true design,” Combs says. “It’s attached on the exterior of the pump panel and can be transferred from one apparatus to another. The valve is extremely reliable and is not susceptible to damage, although it is a rather bulky valve.”

|

| 9 Task Force Tips makes a low profile jumbo ball intake valve (BIV), shown here as a six-inch model installed on the side of a pumper. (Photo courtesy of Task Force Tips.) |

Elkhart’s ball intake valve can be mounted either interior or exterior to the vehicle, Combs says. “It allows you to get into tight locations and is a cleaner profile on the vehicle,” he notes. “Typically ball intake valves are smaller intakes; at four inches or larger, you move to a butterfly valve.”

The Elkhart butterfly valve intake, EB6D, is a six-inch internal intake valve that typically is electrically actuated, Combs points out. “The controls can be located anywhere on the pump panel for this valve, which is a heavy-duty, robust design that can operate up to an eight-inch-diameter [valve].”

|

| 10 Elkhart Brass Company makes ball intake valves that can be mounted either interior or exterior to a pumper or tanker. Shown is Elkhart’s model 9786 piston intake valve. (Photo courtesy of Elkhart Brass Company.) |

Akron Brass recently unveiled its Revolution intake valve. “It’s a patent-pending valve with a hand wheel that wraps around the inlet of the valve,” Durstine says. “The handle on the ball-style valve, available in four- to six-inch sizes, is large enough to create easy leverage for firefighters.” Durstine adds that Akron Brass still offers its Black Max intake valve, a piston-type unit, although the Revolution offers improved friction loss characteristics.

ALAN M. PETRILLO is a Tucson, Arizona-based journalist and is a member of the Fire Apparatus & Emergency Equipment editorial advisory board. He served 22 years with the Verdoy (NY) Fire Department, including in the position of chief.