– March 2013

Ground Ladder Storage: Oops, I Didn’t Think of That

Bill Adams

In the January 2013 issue of Fire Apparatus & Emergency Equipment, the article “Secure Spots for Engine Company Ladders” reviewed options for storing ground ladders on pumpers. This piece elaborates on the topic from the technical perspectives of writing purchasing specifications and realistic fireground operations. Saying, “Oops, I never thought of that,” does little to calm the indignation and wrath of a fire chief because ladders can’t be deployed on his fireground. I do not recommend or endorse a location or method to store ladders. It is imperative to point out that regardless of the method and location, improper apparatus placement on the fireground can hinder or prevent ladder removal.

For simplicity, solid beam aluminum ladders are the basis for this piece. Wood and fiberglass ladders are not addressed. There is no preference in materials used or partiality shown between solid beam and truss construction. Duo-Safety and Alcolite are the principal makers of ground ladders.

|

|

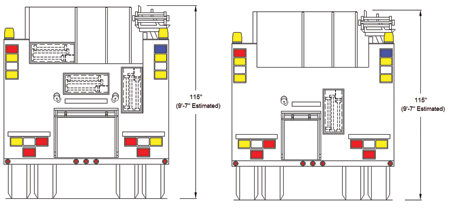

(1-2) The right-hand side swing-down ladder rack remains a constant in these

|

The Standards

Although the National Fire Protection Association (NFPA) 1901, Standard for Automotive Fire Apparatus, section 5.7.1 Ground Ladders requires a folding, a roof, and an extension ladder, it does not specify minimum lengths. Interestingly, NFPA 1901’s Appendix sentence A.5.7.1.2 states, “Where there are no ladder trucks in service, pumpers should normally be equipped with a 35-foot (10.7-meter) extension ladder.” It continues, “It might be advantageous to standardize on the 35-foot (10.7-meter) extension regardless of available ladder truck service.” Going to a 35-foot ladder from a smaller one is more expensive and can dramatically impact the design, size, and layout of a pumper. And, the 35-foot ladder is more labor intensive to deploy.

The Insurance Services Office, Inc. (ISO) requires pumpers to carry a 12-foot roof and a 24-foot extension ladder (aka 12/24), which are what most apparatus manufacturers offer as their standard ladder package for pumpers. Be advised that the 12/24 ladder complement is not specifically required by NFPA 1901. If you operationally need and only want, as an example, a 10-foot roof and a 20-foot extension ladder, buy them. They’ll meet NFPA 1901. It’s unknown how many “points” the ISO would take away for not carrying the 12/24, so it’s advisable to ask the local ISO office. Do it in writing. Your overall ISO classification might not be affected. Then, you can purchase what you want and really need rather than what some regulatory agency says you should or have to carry. Whether that is a prudent decision is up to the fire department hierarchy and the authority having jurisdiction (AHJ). If your purchasing specification and the AHJ do not require the pumper to be ISO-compliant, be wary if a vendor says you have to carry a 12/24. That vendor may be remiss in other areas.

|

|

(3-5) These three storage areas have varying distances from ground level to the ladders.

|

Ladder Storage

Traditional ladder storage for pumpers is “hanging” them on the officer’s side above the rear wheel well with ladders held in place by spring-loaded clamps. Usually the extension’s fly section faces inboard with the roof ladder nestled inside the beams of the extension’s base section. There are advantages to that location. Nesting (aka banking) ladders together takes up about an inch less space than if stored separately. The hanging method is universal, or easily adaptable, in accepting different sizes, types, and manufacturers of ladders. From ground level, a firefighter can easily remove a 12-foot roof ladder weighing less than 30 pounds. A single firefighter should be able to remove a 70- to 75-pound 24-foot two-section extension without blowing a gasket. Finally, it’s inexpensive. Addressing apparatus placement, if a firefighter can open the cab door and get out, there’s probably enough room to remove the ladders.

Specification writers are not always up to date with actual day-to-day fireground operations. They should be. What they write into, or inadvertently leave out of, a specification can affect how efficiently the apparatus and its crew functions on the fireground. As an example, some departments assign one member of the first-due engine company to perform outside ventilation if there is no ladder company service available or prior to one’s arrival. It may require using a ladder. A firefighter, observing an occupant or fellow member trapped on the second floor of a building, could single-handedly remove a ladder from the pumper and effect a rescue. Some fire departments drill on single firefighters retrieving, throwing, and raising a pumper’s extension ladder. If you expect, anticipate, and train for such scenarios, don’t inadvertently shoot yourself in the foot by specifying the wrong ladder or the wrong location to store it.

Slide in the Rear

With the popularity of high side compartments on both sides of pumpers, it’s common to fully enclose ladder storage in the rear of the apparatus. It has merits. But, buyers beware. There are downsides to that location-shortcomings that may not be obvious when reviewing a blueprint, looking at photographs, or listening to a vendor’s sales presentation. In the real word, that 70- to 75-pound two-section 24-foot ladder is more than 14 feet long. With truss construction, it’s more than 15 feet long. When removing ladders stored in the rear, nothing can be parked behind the pumper-not another pumper, an ambulance, the chief’s car, or a police car. You are cooked; you lose. Fourteen to 15 feet doesn’t seem like much, but it can be significant on narrow streets in congested neighborhoods or on long narrow driveways. The ability to stack apparatus on the fireground will be limited by the length of the longest ladder carried.

Slide-in storage, especially fully enclosed, requires custom-built enclosures. NFPA 1901 Section 15.11 Requirements for Mounting of Ground Ladders specifically states ladders are to be mounted in a manner to prevent movement and abrasion. Ladders aren’t supposed to flop around. That has merit. However, it may work against you. Be aware that physical dimensions including closed length, width, and banking distances of similar size ladders differ from various manufacturers. Dimensions also vary between solid beam and truss construction-even from the same manufacturer. A custom-built module to hold one manufacturer’s ladder may not hold another’s in the future. You may be locked into one size, one type of construction, and one manufacturer for as long as you own the rig. Choose your ladders wisely.

Use caution. Regardless of manufacturer, style, or size, ladders have to pull straight out. There’s no bending or tilting when pulling them out of a fully enclosed module. Consequently, weight and location are important. Roof ladders may not pose a problem. But if one firefighter is removing the extension ladder, it may require the expertise of a flying Wallenda walking a tightrope to perfectly balance it. Good luck; don’t get hurt. Some fire departments use bright colored tape to mark the center lines (balance points) of ladders likely to be carried by one firefighter.

|

|

(6) Probably the most common and easiest method to store enclosed

|

Vertical or Horizontal Storage

Ladders can be stored vertically (on one beam) or horizontally (flat on two beams). Give this decision careful consideration. Vertical storage height is usually between waist and chest level when storage is between the booster tank and the rear upper ½ depth portion of a full-height side compartment. Note: It’s not limited to that location. Horizontally stored ladders can slide in just below, just above, partially into, or all the way through the booster tank. Operationally, the stored height can be from just above frame-rail height to well above the head of a firefighter standing on the ground (see diagrams 1 and 2).

The 24-foot extension weighs more than 70 pounds; a three-section 24-foot ladder is close to 100 pounds; and the NFPA-recommended 35-foot extension, in a three-section configuration, can weigh from 130 to 170 pounds. Choose the location wisely. If your specifications do not require a certain height, you’ll probably get the one that’s the least expensive to manufacture. I hope it works for you.

Horizontally stored ladders are usually centered side to side in the rear panel. They don’t have to be. They can be offset to one side, perhaps away from preconnected lines.

|

|

(7) When ladders are stored flat and are intended to be carried by one

|

Ladder storage locations shown on this article’s photos are neither standard nor recommended. Each was custom built to a purchaser’s specification. Photos 3, 4, and 5 and diagrams 1 and 2 show ground ladder storage ranging from just above the chassis frame rails to just above the booster tank. Which is the easiest for two small statured firefighters to remove? Another reminder-because ladders have to pull out straight, sliding out on a beam at waist level is easy and probably safer (photo 6).

When stored flat, ladders can be awkward to remove from and reload on the pumper. Why? Most firefighters carry pumper ladders vertically with one beam on their shoulders or they hand carry them by the top beam. When carried in that manner, they must be rotated 90 degrees when removed or put back to store them flat. Look at the three firefighters in photo 7. Despite a convenient storage height, it appears they could be struggling or, at the least, it doesn’t seem like it’s a natural movement in the evolution. Imagine doing this with limited staffing or by yourself with ladders stored above your head. Good luck.

Swing-Down Ladder Racks

Side-mounted swing-down racks are almost standard with rescue-pumper configurations featuring full-depth and full-height side compartments. Some swing-down racks prevent traditional hinged compartment doors from opening. Wayde Kirvida, factory sales with CustomFIRE, says, “We put limit switches on them. If a hinged door is opened, the rack is inoperable, so they can’t drop with a door open.” Shutter doors (roll-ups) give access to compartments. However, it’s advisable to check with vendors to determine how much room each offers to access oversized or heavy equipment.

How far from the apparatus can or will a ladder rack swing? Answers are all across the board. Ask the apparatus manufacturers; many build their own. Mike Adams, vice president of Ziamatic, a supplier of swing-down racks, says body height usually determines the “distance” away from the apparatus. Custom racks are not uncommon.

Again, apparatus placement becomes important. How far away from a parked car, telephone pole, or mailbox does the pumper need to be to fully deploy the rack? That may pose a problem on those narrow congested streets. On rural roads or private drives, is it possible the deployed ladder rack will end up over a drainage ditch or culvert? “Oops-I never thought about that” (photo 8).

|

|

(8) Consider apparatus placement when evaluating methods of ladder

|

Rear Tilt-Down Ladder Racks

The European fire service traditionally stores ladders on top of the apparatus. Regardless of the mechanics of operation, they work on a fulcrum principal. The rack extends or is pulled away from the rig and then it tilts down. It works like a kid’s see-saw. One half extends downward to the ground and the other half raises up.

Apparatus placement remains relevant. How high does that rack rise up in the air? Beware of overhead obstructions-particularly electric wires-and don’t inadvertently fry your pump operator. Remember to leave room behind the rig to get ladders off the rack after it’s been deployed-especially if you opted to carry longer ladders. A two-section 28-foot ladder is more than 16 feet long.

Specifications

Quite often, specification writers do an inadequate job defining rear slide-in ladder storage. One example states, “Ladders shall be stored in the rear curb side on their beams below the hosebed between the booster tank and the side exterior compartments. A treadplate door shall be provided.” Another says, “Ladders shall be horizontally stored in the rear sliding into a tunnel through the booster tank and be protected by a smooth stainless steel door.” The latter is really weak-you could end up with ladders that slide in anywhere from four feet off the ground to way over your head. Be specific or live with the consequences. Consider addressing the following questions in your purchasing specifications. If you don’t, the manufacturer will. The answers may not be to your liking or benefit. You lose.

• On the rear slide-in storage, what is the maximum distance acceptable from ground level to the bottom of the ladder?

• Is each ladder stored in a separate enclosure?

• Is the door hinged on the left side, on the right side, at the top, or on the bottom?

• Is the door wired to the “open compartment” light in the cab?

• What kind of door handle is required?

• Is the storage module an integral part of the booster tank construction, is it part of the body construction, or can it be a separate slide-in module of any kind of material? Does it matter? Is there a difference in warranty or cost?

• When stored ladders extend into the pump house, are the visible portions supposed to be fully enclosed, or does the pump house itself count as fully enclosing them?

• Are vents and drains required in a fully enclosed ladder compartment? If you store wet or snow-covered ladders in a sealed compartment, it will start smelling nasty and the ladders will always be moist and slimy and become a breeding ground for mold.

|

|

(9) Not commonly seen and probably inexpensive is the ladder

|

Design Ramifications

A ramification is defined as a consequence, a difficulty, or a result. Every ladder storage location impacts apparatus design, the same as it does operational capabilities. Most purchasers are unaware of design ramifications until the vendor calls saying, “Gee, we can’t do this.” Inexperienced purchasing committee members may not grasp the “what ifs” and “what happens” when choices are made. To elaborate, a 12/24 ladder complement hanging on the side of a pumper takes up about 174 by 25 by 12 inches. That’s about 30 cubic feet. If that area is wanted for compartmentation, the ladders could be stored in the rear of the body. If the tank runs the full length of the body, about 200 gallons of water could be displaced. That’s more than 1,600 pounds. Moving the ladders into the hosebed could take up the space equivalent of 400 feet of five-inch large-diameter hose (LDH), 800 feet of 2½-inch, or 1,300 feet of 1¾-inch hose. What does a vendor do-suggest raising the hosebed, lengthening the wheelbase, or proposing a tank with 200-gallon-less capacity?

Swing-down ladder racks can nest above the hose body, but that raises the overall apparatus height by a foot or so. If there’s a height limitation in the firehouse, you can nest the ladders directly on top of the side exterior compartments, but you narrow the width of the hosebed, reducing its capacity. Analyze, prioritize, and compromise. It works all the time.

Ask Questions

Work closely with vendors during your design stages. Request preliminary sketches and blueprints-they are invaluable tools. Ask the apparatus manufacturers what the specific design ramifications are for your choices. It’ll save a lot of grief and aggravation the closer you get to bid time. Make life easy for the rank-and-file firefighters. They use ladders every day-ask for their opinions. Consider ladder weights when picking storage locations. Deploying a heavy ladder from a high, awkward, and precarious position is an invitation for injury. Merely looking at a blueprint, a photograph, or an artist’s rendering of ladder storage may not reflect reality in deploying them on the fireground. Choosing a storage area should be a result of prioritizing fireground functions and analyzing staffing and the physical impact ladder placement has on a pumper’s design.

If you don’t physically try ladders on a similar rig or on a physical mockup in your station, you may be doing an injustice to your taxpayers and a disservice to the firefighters who will have to use them for the rest of their careers. Don’t end up having to say, “Oops, I never thought of that.”

BILL ADAMS is a former fire apparatus salesman, a past chief, and an active member of the East Rochester (NY) Fire Department. He has more than 45 years of experience in the volunteer fire service.