By Bill Adams

National Fire Protection Association (NFPA) 1901, Standard for Automotive Fire Apparatus, is a minimum voluntary standard. No standardized ladder truck meeting its Chapter 8-Aerial Fire Apparatus can fulfil every fire department’s needs.

There are too many variables. This article addresses a recommended ground ladder complement on a generically designed straight ladder truck—not a quint.

My recommended apparatus can access—by itself—the roof in two places and one upper-floor window on four sides of 2½-story residences as well as two-story and perhaps three-story commercial buildings found in many urban and suburban communities. It can perform adequate ladder company duties in other environs.

For this article, multiple blueprints were referenced to formulate a layout most, if not all, manufacturers can meet. Weight ratings; materials; and technical details of the cab, chassis, aerial device, body, and compartments are, at this point in the process, at the discretion of the manufacturers (OEMs).

1 An aerial apparatus ground ladder tunnel. (Photo courtesy of Tom Shand.)

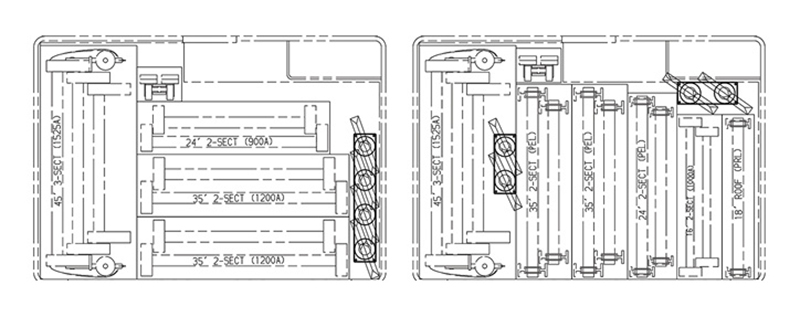

2 Pierce Manufacturing provided these two examples of ground-ladder layouts that could fit in identical size enclosures with the recommendation that, prior to seeking bids or RFPs, specification writers should coordinate with apparatus builders’ sales engineers to ensure their wishlist of ladders and pike poles will actually fit as intended. (Drawing courtesy of Pierce.)

This abbreviated specification is analogous to prebid wishlists apparatus purchasing committees (APCs) disseminate to OEMs saying, “This is what we want. If you can build it, provide your proposed wheelbase, curb-to-curb and wall-to-wall turning radii, recommended chassis components, and suggested purchasing specifications.” In the real world, after evaluating OEM responses, APCs decide—based on local requirements and restrictions—which recommendations and suggestions to incorporate into purchasing specifications. The objective herein is just compliance to the aerial device, specific ground ladder complement, and general layout.

BASIC DESIGN

It is a minimum 100-foot four-section rear-mount aerial without prepiped water, platform, pump, or tank. It has a maximum 140-inch overall height to fit through 12-foot doors, only a six-seat custom cab, and an approximately 235-inch wheelbase and 510-inch (42-foot 6-inch) overall length. The stowed aerial shall not extend beyond the front bumper.

H-style out-and-down stabilizing jacks, which consume the most space on the rig and operationally, were factored in but are not specified. The vertical distance between the turntable and stowed jacks determines the space available for side ladder storage. The side jacks’ horizontal separation determines possible ladder lengths. Dual turntable access can be via permanent recessed steps or out-and-down access ladders located on either side, the rear panel, at “angled” rear body corners, or any combination. Jacks and turntable access are at the OEMs’ discretion.

The body design incorporates a full-height transverse compartment behind the cab; driver’s side (LHS) full-height full-depth compartments ahead of, behind, and over the wheelwell; and officer’s side (RHS) low compartments ahead of and behind the wheelwell.

GROUND LADDERS

The ladder complement, exceeding NFPA 1901, is nonnegotiable. All are compliant with NFPA 1931, Standard for Manufacturer’s Design of Fire Department Ground Ladders (2020 ed.). Extensions shall be two-section, and roof ladders have double hooks. When stowed, like size ladders from different manufacturers can vary in length, width, and banking dimensions. Ladders can be from different manufacturers, and styles can be truss, solid beam, or a mixed combination to maximize storage space. Priority is making all specified ground ladders fit.

The ladder complement is one 45-foot, one 24-foot, two 35-foot, and two 28-foot extension ladders; two 20-foot and four 16-foot roof ladders; two 6-foot wall ladders; one 10-foot folding/collapsible ladder; one 8-foot/13-foot combination step/extension ladder; and one 10-foot Fresno-style attic extension ladder. Why so many? A ladder company is supposed to gain access by climbing up into, down into, to the top of, and over buildings and obstacles—some of which may be inaccessible from the aerial device.

LADDER STORAGE

Provide rear storage for the 45-, the 24-, one 28-, and both 35-foot extension ladders; both 20-foot roof ladders; the 10-foot folding/collapsible ladder; and four pike poles. Ladder tunnel heights and widths under the turntable through the torque box vary among manufacturers. Roll-up and hinged doors and hardware can reduce usable door openings. Provide a removable vinyl/hook-and-loop cover. Mechanically secure ladders internally. OEMs can store ladders vertically, horizontally, or both ways. (See photos 1 and 2.)

Store two 16-foot roof ladders, one 28-foot extension ladder, and the 10-foot attic/extension ladder above the RHS compartments. The 8-foot/13-foot combination step/extension and two 6-foot wall ladders slide into the transverse compartment accessible from both sides. Mount a 16-foot roof ladder and pike pole on each side of the aerial’s base section.

SPECIFY

Specifications should include the following:

- Minimum 4-inch rear bumper.

- Adjustable shelving tracks in all compartments. Purchase shelves and slide-out trays later only as needed.

- Open or closed coffin-style compartments in the available space above the LHS compartments and the RHS ladder storage for a removable ladder pipe and hose or a stokes or tools for “roof” work.

- Portable generator. Don’t specify a permanent generator “just because you’ve always had one.” This is a ladder truck, not a heavy rescue. Besides, the trend is for battery-powered smoke ejectors and power tools.

- Multiple 12-volt LED scene and work lights.

- Removable panels in body compartments to access rear ladder storage modules for future modifications.

POINTS TO CONSIDER

Approximate wheelbase and overall length dimensions were specified allowing OEMs leeway in designing the apparatus. Custom cab and chassis dimensions vary. Two manufacturers’ blueprints of similar ladder trucks have around 225-inch wheelbases and 41-foot overall lengths. Neither featured a design requiring only two-section extension ladders, a minimum rear bumper length, and the ladder tip protected by the front bumper.

This rig may not work for departments with unique challenges such as congested urban environments, restrictive travel height and weight limitations, and fire loads requiring frequent use of elevated master streams. It should, however, meet my objective of accessing roofs and upper-floor windows as previously described.

Don’t diminish a rig’s capabilities to meet subjective whims such as wanting a ladder truck just like your neighbor’s, purchasing the brand the chief’s brother-in-law sells, or buying one with a single rear axle just because it looks good. Prioritize wishes, needs, and necessities.

Don’t reduce the ground ladder complement for extra compartmentation to carry “stuff” that will never be used to reach trapped victims or firefighters.

Don’t self-design ladder storage modules down to the millimeter. Apparatus and ladder manufacturers have specific requirements and recommendations for storing ladders. Work closely with them.

NFPA 1931 compliant overwidth and nonstandard length extension and roof ladders are available from ground ladder manufacturers. Don’t overdesign a $1 million fire truck around a ladder that can be customized for a couple hundred bucks. If a 35-foot extension ladder doesn’t fit, will a 34-foot fit without compromising operational capabilities?

One roof ladder banked inside another with an oversized width takes up less space than banking two separately.

Banking thicknesses can increase from 30% to 40% when going from two-section to three-section ladders. There’s adequate length in this recommended rig’s ladder tunnel but limited width and height.

Extension and ground ladder widths can vary by two inches among models and manufacturers. What are the widths of your existing ladders?

This proposed design will exceed NFPA 1901’s requirement for compartmentation. Bear in mind that NFPA 1901 has “shall have” and “recommended” lists of ancillary equipment. Choose wisely.

Don’t get bogged down arguing about small things like paint schemes/colors, compartment lights, sirens, warning lights, lettering and striping, etc. Take care of the big stuff first. If the apparatus doesn’t carry enough adequately sized ladders to do the job, it doesn’t matter what color it’s painted or how loud the siren is.

BILL ADAMS is a member of the Fire Apparatus & Emergency Equipment Editorial Advisory Board, a former fire apparatus salesman, and a past chief of the East Rochester (NY) Fire Department. He has 50 years of experience in the volunteer fire service.