By Bill Adams

Part 1 appeared in the January 2024 issue.

Following is the continuation of my interview with Wyatt Compton, product manager for Spartan Emergency Response (Spartan ER); Joel Konecky, SVI Trucks vice president of sales; Dave McAlice, eastern regional vice president for Pierce Manufacturing; Ed Boring, fleet sales manager for HME-Ahrens Fox (HME-AF); and Mike Watts, national sales manager for Toyne, Incorporated. Coffin compartments on pumpers and rescues can be ideal yet hazardous locations to store ancillary fire equipment.

When providing coffin compartments, is there a recommended method of accessing and egressing the top of the apparatus body?

Konecky: For rescues, we recommend a rear access stairway. It is always the safest and best option to gain quick access to upper storage. On an engine or rescue that the customer cannot give up the space that a stairway needs, SVI has designed a ladder on the rear of the apparatus that folds up against the body when not in use and can be quickly and easily folded out at an angle to provide safer and easier climbing on and off the apparatus. Another popular design is the lift-up stairway. Most lift with electric actuators or hydraulic cylinders, but we advise against this as it blocks access to your upper storage when in use and only gains a very small amount of additional space.

1 FAMA states its safety signs offer OEMs an option to standardize signage. NFPA 1900 does not require FAMA signs in every area of its document including, Section 12.6 – Stepping, Standing and Walking Surfaces. SVI provides a very simple and understandable “Not a Step” warning sign for compartment doors that are not designated stepping surfaces. (Photos courtesy of SVI Trucks.)

2 This pumper has coffin compartments above the exterior full-depth high-side compartments. Each lift-up cover has a single recessed twist-to-open latch and a “Not a Step” warning sign.

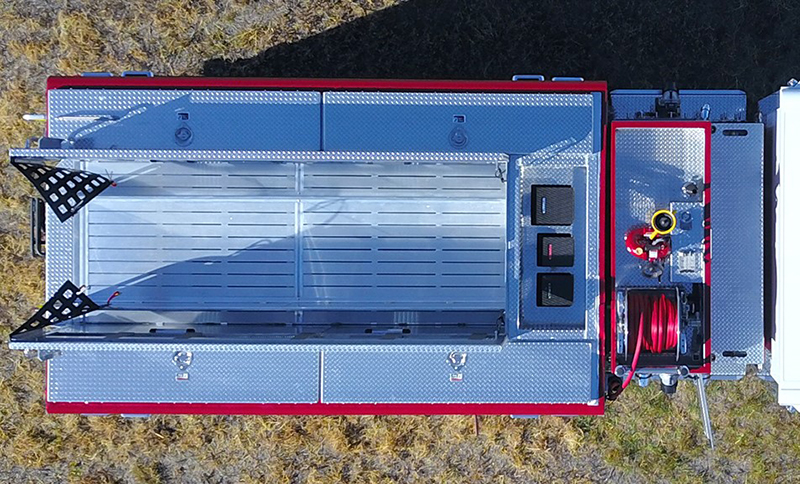

3 The same pumper in Photo 2, also with the dual hosebed covers in the open position. If the hosebed is empty, it can be a long reach to access coffin compartment storage. Rear access to the top of the rig is via a permanent vertical bolt-on ladder. There are no rear panel access doors to the coffin compartments. Note the LDH hose clamp on the rear step and horizontal hand holes in the hosebed dividers.

Compton: This is part of the critical planning conversations that fire departments need to have. The short answer is typically from the rear of the apparatus with an access ladder that deploys when accessing storage compartments. You need to keep in mind how you’ll climb WITH equipment. When we’re talking about a rescue, the walkway area tends to be unobstructed. However when we’re talking about a rescue-pumper, this conversation becomes more difficult.

Firefighters need to think about the conditions in which they’ll be accessing equipment, with and without hose; will they be standing on slippery LDH? Do you have a low hosebed with tall dividers that may make access difficult when the hose is laid on the ground? Don’t hesitate to give yourself multiple options for grab handles at the rear and on top—if you’re in inclement weather or the apparatus is parked on slopes, your footing will be drastically different than when you’re on the truck on flat ground in dry conditions. Hose restraints—consider how you’ll be accessing the upper compartments with either a hose tarp or a hard cover. If you have a hard cover, consider integrating the upper compartment door and the hard cover doors together. While the door may not be for everyone (windy areas), the door opening outward does offer somewhere to mount extra lighting and gives a more substantial barrier for fall protection.

Boring: Typically up the rear of the apparatus using solid hosebed doors as the walking surface. I recommend using a ladder access in lieu of fold down steps.

Watts: Most Toyne apparatus with coffins will have a ladder on the rear of the truck to access the top.

McAlice: On rescue-pumpers, we offer a rear corner access ladder, either a Zico pool-type or, at Pierce, we’re partial to our PUC-style ladder, which deploys and locks at a comfortable climbing angle and has integral slide-down access steps for easy access from the ground. Other popular options include side or rear staircases (fixed or lift-up style) or, in some cases, a slide-out-and-drop staircase with handrails. Once atop the body, a center walkway offers easy and safe access to all equipment.

When providing coffin compartments, do most designs require separate warning lights for the upper rear and upper rear side of the body?

Boring: HME-AF’s warning lights are typically mounted on the sides in the upper zones. They have minimal impact on the available space in the compartment.

Konecky: No additional lighting is required. However, there are advantages to the additional space and height available. There is additional room for more lighting to be installed if the customer chooses and allows the lighting to be placed higher on the body, providing fewer shadows for scene lighting and better warning light visibility for oncoming traffic.

McAlice: When hatch compartments are closed, they are nearly flush with the top of the apparatus body and do not require additional warning lights.

Compton: Most often times, yes, but fire departments do have options. Spartan ER has design options such as notching the body to allow a conventional style rotator.

Watts: Separate lights are not required above the minimum to meet the NFPA. However, most departments will add extra lighting in this area.

Do you have any recommendations, cautions, or “words of wisdom” when prospective purchasers want coffin compartments?

Watts: On a pumper, the access is usually from the hosebed area. If there is a hard cover over the hosebed, the department has to be careful about considering this a walking surface. It is called a hosebed cover for a reason as that is the primary function. You can use yellow tape to mark the edges, but you should have a 36-inch-high handrail system to be compliant with OSHA. This is not a problem for rescue trucks as they usually have a center walkway designed for just that: walking on it.

McAlice: The only recommendations include carefully reviewing your intended equipment list and to avoid storing very long or heavier items that could be awkward or dangerous to unload when needed in a hurry. Be situationally aware of being on TOP of the vehicle. We liken this to when a pump operator is up on top running a master steam, or when personnel may be on or inside the hosebed. Your footing and contact points are critical for firefighter safety.

Compton: “Boots on the ground” should be the primary objective when having conversations about how an apparatus can be configured to store the commonly used equipment. If you have roll-up doors, don’t be afraid to use that space behind the roll-up doors to access items from the rear of the apparatus. Always consider what this access will look like in bad weather with the apparatus parked on sloped ground. This will likely be your spot to store equipment for unconventional situations, and those situations always seem to be in unconventional conditions, so plan for safety!

Konecky: Upper body storage is a great place to store lightweight equipment or supplies, like oil dry/mats and containment booms, as well as equipment that may only be used occasionally. Storing heavy equipment is never recommended due to increased possibility of injury from getting heavy equipment to the top of the truck and removing it when needed on an emergency scene. If heavy equipment is to be stored, SVI recommends customers specify a utility crane so heavy items can be safely raised and lowered from the top of the apparatus to prevent injuries rather than carrying heavy items up and down the access ladder.

4 This rescue truck has a powered rear stairwell, offering reasonably safe access to and from upper compartments especially when carrying equipment. Each cover has a lift-to-open handle, the “Not a Step” sign, and a full-width hat-section reinforcement. Manufacturers have their own methods of reinforcing covers.

5 A fixed rear stairwell is provided on this hazmat rig to access upper storage. There is a removable electric crane in position to lift heavy equipment from a side exterior compartment. Could it be used to remove, replace, and lower equipment from the coffin compartments? When not used, it is stowed in one of the upper compartments.

Boring: I would say prioritize your compartment space. Items carried in coffin compartments take time to retrieve and consume more firefighters to get them down to the ground. Items should be seldom used and low lifesaving priority. It’s a long way up there and high off the ground. Be careful. Falls happen!

NFPA 1900 AND RESPONSIBILITY

The lift-up covers on coffin compartments are similar to the aprons covering extended front bumpers. Both are cosmetic or protective coverings not normally intended as walking surfaces. They are seldom explicitly designed as a stepping or standing surface. If intended to be so, purchasers should specifically note that requirement according to National Fire Protection Association (NFPA) 1900, Standard for Aircraft Rescue and Firefighting Vehicles, Automotive Fire Apparatus, Wildland Fire Apparatus, and Automotive Ambulances. In its Annex A—Explanatory Material “for informational purposes only” on page 1900-253, the first three sentences in Section 12.6.4 state: “Apparatus are constructed with surface areas that are not intended to be used as stepping, standing, and walking areas. These include cosmetic and protective coverings on horizontal surfaces. During the design stage of the vehicle, purchasers should designate which areas are stepping, standing, or walking areas.”

A “shall be” requirement in the standard is in Section 12.6.1.6, which states: “Designated horizontal standing or walking surfaces higher than 48 in. (1220 mm) from the ground and not guarded by a railing or structure at least 12 in. (300 mm) high when measured with the apparatus at curb weight shall have at least a 1 in. (25 mm) wide safety yellow or orange line delineation that contrasts with the background to mark the outside perimeter of the designated standing or walking surface area, excluding steps and ladders.” Curb weight is the total weight of the complete vehicle less the payload. Plainly put, surfaces four feet above the ground that are intended to be used as stepping surfaces have to be outlined. Section 12.6.4.1 goes on to state surfaces designated as standing areas have to be slip-resistant per Section 12.6.4* Slip Resistance.

It is the purchaser’s responsibility to designate areas the manufacturer must fabricate to be NFPA-compliant as stepping, standing, or walking surfaces. Don’t blame the apparatus manufacturer for not complying with a requirement you did not specify! It is also the purchaser’s responsibility to instruct firefighters what they can and cannot stand on when washing the cab windshield and when loading hose and accessing equipment on top of the apparatus.

FAMA

The Fire Apparatus Manufacturers’ Association (FAMA) has published a paper designated TC010 describing fire apparatus safety signs (www.fama.org/wp-content/uploads/2018/01/TC010-Fire-Apparatus-Common-Safety-Signs-220224.pdf). It states, “This document gives the fire apparatus manufacturers an option to provide standardized product safety sign text and artwork for common hazards.” On page 10, sign number 26 states it is for a “no-step” hazard for use “on any horizontal surface that would be tempting to step on but that is not provided with slip resistance surface and grab handle.” The wording on the sign itself reads “Full hazard—ratings not provided” and “Not intended for stepping, standing or walking. Fall will injure or kill.” The wording is on an ANSI-compliant 3½- × 3½-inch tag with a diagram of a foot with a line through it. NFPA 1900 requires FAMA signage in some areas of the document—but not in all.

It is debatable whether or not a 3½-inch square size sign will prevent firefighters from inadvertently or purposefully standing on “undesignated” surfaces.

6 Rear access to the top of this rescue-pumper is via a unique swing-down and tilt-out ladder. A full-width step is provided below the hosebed, probably to access the rear hinged access door to the right-hand side coffin compartment. The rear step (aka rear work platform) is a decent size for loading hose.

7 This rescue-pumper’s midship pump panels are recessed behind exterior roll-up doors. The only way to access coffin compartments and to provide access to the light tower, booster reel, deck gun, and booster tank and foam manual fill towers is from the rear of the apparatus. The size of a manufacturer’s standard hosebed or coffin compartment cover may necessitate extra reinforcement to meet NFPA 1900’s minimum 500-pound weight requirement for a stepping and standing surface. It is the purchaser’s responsibility to specify which surfaces are to be used for walking or standing. Be fair to the apparatus manufacturers—specify the realistic weight a coffin compartment or hosebed cover is expected to support.

ONE HAND FOR ME AND ONE FOR YOU

For years, I have professed that if firefighters have to climb onto a fire truck to access a primary piece of equipment, someone did a lousy job designing the apparatus. It also applies to coffin compartments. The first sentence in NFPA 1900 Appendix A Section A.12.2.1 seems to agree: “Firefighter injuries resulting from climbing on apparatus to retrieve, store, and operate equipment can be minimized if specifications require that equipment be accessible from ground level.”

I acquiesce that the tops of apparatus are, and probably will have to be, used to store “some” equipment. In agreeing so, my caveat is both buyer and seller should ensure the safety of the firefighters when accessing equipment stored on top of a fire truck. Again, NFPA 1900 seems to concur. In Section 12.7—Access Handrails or Handholds, Section 12.7.5 states: “Handrails and handholds shall be constructed so that three points of contact (two hands and one foot, or one hand and two feet) can be maintained at all times while ascending and descending.”

My supposition is the NFPA only wants one hand to be used to carry equipment up or down. Purchasers should consider that when determining what equipment is going to be carried in coffin compartments and how many people will be required to retrieve and put it back. Is there a reasonable weight that can be handled when perched on an access ladder or steps? How about a spare 5-gallon pail of foam?

Awkward size equipment should also be evaluated. As an example, consider a 10-foot length of semirigid hard suction hose located in a coffin compartment accessible from a rear hinged door. When standing on an access ladder or steps, is it safe for a firefighter to slide out the hard sleeve or even a rigid 10-foot-long pike pole with one hand while hanging on with the other hand? It could be 11 feet off the ground. What’s a firefighter’s horizontal reach, about 3 feet? How high can the average firefighter reach with an extended arm, 7 or 8 feet?

PURCHASING SPECIFICATIONS

The purchasing specification read: “Two coffin compartments shall be provided on each side of the main hosebed with lift-up treadplate doors.” Based on the preceding manufacturers’ commentary and accompanying photographs, those 19 words are insufficient to accurately describe coffin compartments—unless the purchaser doesn’t care.

- Are there minimum size requirements for the compartments?

- Is there an acceptable material, gauge, and type of construction for the compartments?

- Are compartments add-ons or an integral part of the body construction—welded or bolted?

- What material and gauge are the covers to be?

- Are covers to be NFPA-compliant designated walking surfaces?

- If a designated walking surface, is there a weight requirement for the covers?

- If door hat-section reinforcements are required, what size is acceptable?

- What type of latches and how many are required per compartment door?

- What type and how many hold-open devices are required per door?

- If grab handles are required to raise the doors, what size and length do you want?

- What type of compartment lighting is required—size, location, and number per compartment?

- If drains are to be provided, what size are they and where do they terminate?

- If internal dividers are required, are they permanent or adjustable fore and aft?

- If there is external lighting on the outer facing exterior surfaces, are internal protective covers required inside the coffin compartment?

- When specifications specify a maximum overall height for an apparatus, is that measurement supposed to be to the top of the apparatus body, to a deck gun, to a telescoping light, to the cover on a coffin compartment, or to a grab handle located on a coffin compartment cover?

Firefighter safety is priority one. Don’t inadvertently jeopardize it when specifying coffin compartments. If a requirement is not in writing, it does not exist. Good luck.

BILL ADAMS is a member of the Fire Apparatus & Emergency Equipment Editorial Advisory Board, a former fire apparatus salesman, and a past chief of the East Rochester (NY) Fire Department. He has 50 years of experience in the volunteer fire service.