Bill Adams

If you shop for a recliner to watch the Sunday football games, there’s a reasonable chance you’ll sit in it before purchasing. It’s the same when buying a new mattress. You want to make sure both are comfortable. You wouldn’t think of putting a down payment on a new automobile unless you test drove it. Why would you buy a new pumper without giving serious consideration to how you will access your primary equipment-the fire hose? Equally as important as accessing the hosebed to pull a line is providing a safe place to stand to repack it. It’s lamentable to take delivery of a new pumper and discover firefighters cannot efficiently deploy a line. It’s embarrassing if they have an equally challenging time trying to reload it. The same applies for any piece of apparatus when access, for whatever reason, is provided to the roof or upper sections. Yet, it happens all the time. This article mainly addresses a pumper’s working end.

Fire departments will spend a half- million dollars for a new rig with no real forethought on “access.” Consequences can be significant; somebody can get hurt. In my opinion, if you have to climb onto your rig to reach its primary piece of equipment, you may have done a poor job of designing it. If you place firefighters in a precarious and unsafe position to put that or any equipment away, you’ve done an equally questionable job. And, if they get hurt doing either, your inaction may be irresponsible. Be careful; you may be held accountable.

NFPA 1901

National Fire Protection Association (NFPA) 1901, Standard for Automotive Fire Apparatus, addresses steps and stepping surfaces in detail in Sections 15.7 and 15.7.4. Purchasers should refer to it. It specifies minimum sizes, slip resistance, spacing, certifications, and so on. Section 15.8 addresses handrails and handholds. Although you shouldn’t be stepping on a handrail, its location is essential when climbing on, off, or to the top of a rig-especially when you are carrying something. Handrail locations make steps functional.

Section 15.8.5 states, “Handrails and handholds shall be constructed so that three points of contact (two hands and one foot, or one hand and two feet) can be made at all times while ascending and descending.” The “three points of contact” is the same theory promoted in climbing ground ladders. Bear in mind, an access step is not a ground ladder, nor is it considered an access ladder or a work platform. What are you going to use it for? Just because manufacturers supply compliant access steps does not necessarily mean the steps are safe or easy to climb-especially in full turnout gear (photo 1). The NFPA does not define safe or easy. They are vague terms subject to personal interpretation. If exact quantities, specific sizes, and locations for access steps are not specified, manufacturers are only obligated to supply the minimum number, size, and spacing required by NFPA 1901.

|

| (1) This unit has three folding steps and a permanent step at the left rear. However, the bottom folding step is tucked underneath the permanent step. How do you access it going up? On the way down, if you can’t see it, chances are you might miss it altogether. (Photos by author unless otherwise noted.) |

Intent

Intent can be defined as an aim, a goal, or an objective. Other than just being NFPA-compliant, what is your objective in specifying access steps on a fire truck? My opinion is the NFPA’s intent in mandating access steps is to provide a reasonably safe means to get on and off the rig. That’s it. An access step may not be designed or intended by the manufacturer (or the NFPA) to provide secure reliable footing for a firefighter while concurrently executing another mission. Ask your apparatus dealer what you can use an access step he supplied for, and get it in writing. The least number of minimum-size compliant steps may help you reach equipment on top of the rig, but what do you do with the equipment after you’ve reached it-carry it down, hand it down, or throw it down? Remember the three points of contact.

If the purchaser intends to provide a stable and secure area while performing a task such as reloading hose; operating a monitor; or removing a hard suction sleeve, a ladder, or a spare five-gallon pail of foam, more than minimally compliant access steps may be in order. Don’t inadvertently invite an injury by being complacent.

The Rear Step

Gone are the days of the 18- to 24-inch-deep full-width rear steps-also known as the back step and the tailboard. There is no discussion, qualms, or regrets about banning “riding the rear step.” Those days are history; let them go. However, the fire service may be inadvertently shooting itself in the foot by shrinking their size and even eliminating them. Discounting the former riding positions, the tailboard served as a stable work platform as well as a rear bumper. In minor rear end accidents, it could prevent significant damage to bodywork and exposed plumbing (photo 2). Whether to be politically correct or to avoid liability, today’s specifications refer to rear steps as rear work platforms or rear bumpers or do not refer to them at all. Chances are, if you don’t spec it you don’t get it.

|

| (2) There is no rear step or bumper on this rig. The rear drop-down door serves as the lowest access step. When the step is in the stowed position, the five-inch connection followed by the rear body panel will take the first hits in an accident. |

Manufacturers and purchasers strive to get the most in compartmentation for the plethora of ancillary equipment carried on today’s engines. What is more important: carrying an extra piece of nonengine company oriented equipment or safely and efficiently deploying and returning your primary tool-the fire hose-to service? That full-width former rear step, which put a firefighter two feet closer to the top of the hosebed, made hose evolutions much easier.

A pumper with a hosebed 72 inches above a 24-inch-deep by 100-inch-wide rear step devotes 100 cubic feet of work space for firefighters. That equates to more than 16 square feet of standing space. Proponents clamoring for more compartmentation salivate at the possibility of using those 100 cubic feet for carrying more equipment. Hence, compartments are getting bigger and the rear step is fading into history. What is your priority: increasing the amount of equipment you carry or providing a safe working environment for the firefighters? Can there be a happy medium without compromising firefighter safety? Don’t forget accountability. It’s in the dictionary before liability.

|

| (3) This unit shows an access ladder in the stowed position. The apparatus manufacturer has provided a standing area on the top of the rig plus a full-width lower rear step. |

Access Ladders

Recent trade shows have shown a large number of job-specific ladders on the back of apparatus accessing both hosebeds and roofs (photo 3). Remember the old saying in your probie class about climbing ground ladders: feet to the middle, hands to the outside, and keep your arms straight? Forget that when crawling up the back of a fire truck. Access ladders on fire apparatus are not the same as ground ladders. The ideal climbing angle for ground ladders is around 75 degrees. NFPA 1901 Sentence 3.3.3 defines an access ladder as “one or more rungs (of any shape) for climbing that have a degree of inclination between 60 and 90 degrees.” The back ends of most fire trucks are perpendicular to the ground-90 degrees.

That is straight up and down. When climbing a ground ladder, there’s a natural tendency to lean forward into it. Climbing a vertical ladder is more challenging. Climbing to the top of a rig with access steps vertically inline with each other (photos 4 and 5) can be akin to climbing a pompier ladder. If you have never climbed one, don’t bother. It’s not easy, it’s not fun, and it’s not recommended. And, don’t attempt it in full turnouts while carrying a tool. Some training manuals say climbing a ground ladder should be done “smoothly and rhythmically.” Climbing access steps or access ladders on a rig should be done smartly, slowly, and safely. Apparatus manufacturers and their component part suppliers offer all types and sizes of apparatus access ladders. Standard sizes and built-to-order units with various widths and angles of inclination are available. Consult your favorite apparatus dealer. Whatever you choose, keep the troops safe.

|

| (4) Seven access steps are provided on the rear of this rig along with a lower rear step. |

Rungs, Steps, and Platforms

NFPA 1901 does not specify the stepping area of the rungs on an access ladder. Sentence 15.7.3 notes that the slip resistance of the rungs does not have to be as aggressive as that on an access step or work platform. Are you less likely to slip on an access ladder’s rung than you are on a work platform or an access step? What if you are doing the same job? Sentence 15.7.1.2 mandates an access step must be a minimum of 35 square inches, a five-inch-wide disc must fit on it without overlapping the edges, and that there is no obstruction for eight inches from the leading edge of the step. Some vendors supply premanufactured steps in widths up to and including 24 inches (photo 6), and most apparatus manufacturers will custom build them to size. Sentence 15.7.1.3 states “all platforms” must be a minimum of eight inches deep but does not specify a minimum width. What is the difference between an access step and a work platform? I can’t find it. Ask your apparatus salesperson. Would the definition matter to the fire department’s insurance carrier if a firefighter was injured?

|

| (5) Climbing to the top of a rig with access steps vertically inline with each other can be akin to climbing a pompier ladder. |

NFPA 1901 Annex A, sentence A.15.7.1.2 states, “The intent of step size and placement requirements is to ensure the firefighter’s foot is supported seven inches to eight inches (175 mm to 200 mm) from the toe when the foot is placed on the step in the normal climbing position.” A size 11½ boot is 4½ inches wide by 13 inches long-a standing area two thirds larger than the minimum stepping surface required for an access step and anyone’s guess for how much larger than the surface area of an access ladder’s rung.

The objective here is not to condemn, criticize, or promote steps, platforms, rungs, or the NFPA’s requirements. It is to make buyers aware. If a purchaser’s intent is to use a step, steps, or an access ladder as a platform for a firefighter to remain stationary while performing a task such as reloading hose, removing and handing down (or up) equipment, or operating a monitor, you might consider giving the firefighter more than 35 square inches to stand on. What size stepping areas (and how many handrails) are appropriate if the firefighter has to carry that equipment up or down? What would you personally want if you were the one removing a portable monitor from the top of a rig? Remember “one hand for me and one hand for thee.” If you have one foot on a step and the other foot on the next step 18 inches directly above it and you’re hanging onto a handrail with one hand, what size and how heavy a piece of equipment can you handle with your one free hand (photo 4)? Can you do the same jobs standing on an access step, a work platform, and an access ladder’s rung? Are you supposed to? Good luck; don’t get hurt.

|

| (6) The rear of this apparatus incorporates a rear tailboard, access steps larger than the NFPA’s minimum requirement, and handrails that appear to make access and egress user-friendly. |

Writing Specifications

Steps, standing surfaces (work platforms), and access ladders may be interpreted in different ways by different people. If you really want a work platform, say so. And, specify the minimum size you want. It is a challenging task to write “access requirements” in a set of purchasing specifications. In today’s litigious society, purchasers should be cognizant that they could be subject to legal ramifications should an injury be sustained by an employee who has been provided with an inappropriate tool or an unsafe working environment. There is no inference or suggestion as to what is a safe working environment. Leave that to the legal and safety experts.

|

| (7) This rig has designated stepping areas at the bottom of the hosebed and at each side at the recessed setback to the rear compartment. It is the result of a culmination of ideas, sketches, artist’s renderings, specifications, and blueprints. |

A “seasoned” member of an apparatus purchasing committee may not have physically accessed a hosebed in many years, yet that person may specify the method of access firefighters will have to use for many years. That doesn’t seem right. Looking at a blueprint depicting access steps leading up to a hosebed is not reality. A blueprint is a two-dimensional illustration, albeit to scale. Have your department’s or company’s oldest, largest, and smallest active members don turnout gear and physically access the hosebed of a similar rig. Have those firefighters perform the tasks you expect them to perform on scene. If there’s a remote possibility that a “packed up” firefighter has to return to the rig and retrieve a piece of equipment via access steps, have him try that too. Is he supposed to do it alone?

Make sure your specifications reflect the results. Stacked inline steps may look good on paper or in a photograph, but try climbing them. Worse yet, try to climb down them. Good luck again. Did you ever wonder why ground ladders have beams on each side but many access steps have handrails on one side only (photos 4 and 5)? What happened to three points of contact and “one hand for me and one hand for thee”?

|

| (8) This new rig has the time-proven accessibility of a full tailboard, a recessed intermediate rear step above the booster reel, fold-up steps at each side, five separate handrails, and hand hole cutouts in the hosebed dividers. It looks easy to work off of. (Photo by Brian Horrocks.) |

Be very definitive in specifying sizes and locations for your means of access. Do not use phrases and descriptions such as “safe,” “easy,” “to provide safe footing,” “easy to climb,” “secure standing area,” “user-friendly,” and “easily accessible.” You can’t define them and you can’t compare each manufacturer’s interpretation of them when evaluating bids.

Concept to Finished Product

Quite often a purchaser’s written description of what it wants does not give potential bidders an accurate understanding. It’s not illegal to provide sketches in your purchasing specifications to show prospective bidders what you want.

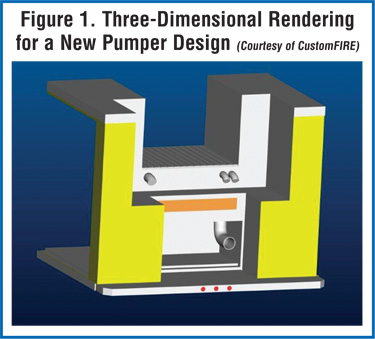

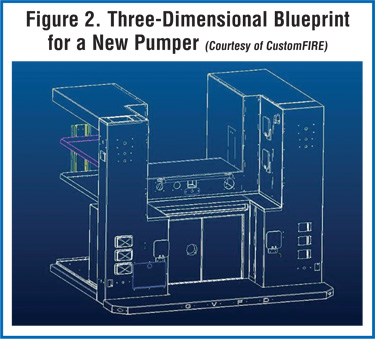

Purchasers should not underestimate the value of requiring bidders to provide three-dimensional drawings and illustrations with their bid packages. Wayde Kirvida, factory sales with CustomFIRE, notes that three-dimensional renderings can also be important factors in the apparatus design phase when purchasers evaluate the capabilities of manufacturers. Figure 1 depicts one such three-dimensional rendering for a new pumper design. Figure 2 shows a three-dimensional blueprint of the same unit, and photo 7 shows the finished product.

|

| (9) Both sides at the rear of this CustomFIRE pumper for the St. Paul (MN) Fire Department have full height handrails on each side of custom width access steps to facilitate climbing while meeting the three-points-of- contact concept. Just visible on the compartment tops are the ends of two additional grab rails. |

There are a multitude of solutions for accessing equipment on a rig. It makes no difference which is used as long the unit provides a safe working environment for the firefighter (photo 8). It is bad enough that firefighters are put in harm’s way when entering a burning structure or mitigating hazardous situations. They should not be subject to unnecessary injury when accessing and returning equipment to their rigs.

BILL ADAMS is a former fire apparatus salesman, a past chief, and an active member of the East Rochester (NY) Fire Department. He has more than 45 years of experience in the volunteer fire service.