Alan M. Petrillo

Ambulance manufacturers are getting ready to meet the challenges to the design and form of their rigs that the coming National Fire Protection Association (NFPA) 1917, Standard for Automotive Ambulances, will bring. The standard is expected to be issued on January 1, 2013.

Planning Now

Although the 2013 standard isn’t issued yet, a number of changes have been noted in the document that could affect ambulance specifications. These include a seat belt monitoring system that gives both visual and auditory alarms in the cab and patient compartment if someone isn’t wearing a seat belt, a 171-pound capacity for each seated position, tire pressure monitoring, zone and underbody lighting to replace the KKK-A-1822F lighting standard, a speed limiter or governor to regulate a maximum speed of 77 miles per hour, carbon monoxide detectors for gasoline-powered ambulances, interior cab maximum weight ratings, and a mandatory color scheme for chevrons (red and yellow or fluorescent green).

Paul Holzapfel, national sales manager for Wheeled Coach, says his company has already begun testing its designs to be sure they meet the requirements that will be set forth in NFPA 1917. “A lot of what’s in the new standard are the things we have to have on our vehicles, like monitored seat belts,” he says. “The issue is that we have to place sensors in the captain’s chair and squad bench seating so they work all the time when a person is in the seat.”

|

| (1) Wheeled Coach built this medium duty ambulance on an International TerraStar chassis for Martinsville (VA) Fire & EMS. (Photo courtesy of Wheeled Coach.) |

Holzapfel notes the standard also will have maximum load ratings that will affect interior cabinets. “The cabinets will have to be rated for the type of equipment they will hold,” he says. “We plan to offer different options to customers, depending on the type of latch or lock mechanism they choose for the doors.”

Holzapfel says the standard also has a new test for brackets. “Any bracket that holds anything more than three pounds has to be tested to 10 Gs,” he points out. “A fire extinguisher is one of those pieces of equipment. If it’s in a cabinet, that cabinet has to withstand the 10 G test all around-top, bottom, front, back, and sides.”

Varied Adoption Rates

Chad Newsome, national sales manager for PL Custom Body and Equipment Co. Inc., says that although NFPA 1917 will be issued in January, there’s no guarantee that the regulatory groups in various states will adopt the standard because of the increased cost it will mean in ambulance specs. He estimates the increase in cost to run between $6,000 and $10,000 on a typical ambulance.

“While the concept of the standard is wonderful, there needs to be uniformity in adopting it,” Newsome says. “The existing KKK-A-1822F Revised, designed as a purchasing standard for the federal government, was adopted in 2007 by the General Services Administration. Some states have strict adherence to KKK, while others comply with it somewhat, but we don’t know what they will do with the 2013 NFPA 1917 standard.”

|

| (2) This PL Custom Body and Equipment ambulance built for the Wilton (NY) Fire Department features a medic seat on the curb side of the interior that can slide forward and rearward on a track. (Photo courtesy of PL Custom Body and Equipment Co. Inc.) |

Safety Factors

One of the biggest issues in ambulances revolves around safety-both for the patient and the crew, Newsome observes. “Safety in ambulances continues to be talked about and worked on, with ambulance manufacturers using safe construction methods and building safe designs.”

However, safety by the end users of the rigs is a major issue, Newsome believes. “PL Custom starts with the assumption that people won’t wear seat belts, so we make them wear them,” he says. “We make both retractors extend for our belts because some people are horizontally enhanced and we want to accommodate them.”

Other safety elements in PL Custom ambulances include countertops and cabinets that are radiused at 45-degree angles so there are fewer strike points in the patient compartment. Countertops also have rounded edges so there are no hard angles on them, Newsome points out. “We also put in crash rails at side impact points and about 12 inches down from the top of the compartment,” Newsome says. “These double crash rails are five-inch by two-inch frame rails around the truck and on the doors and compartments to give an extra level of safety to the passengers.”

Mark Schwartzbauer, sales manager at Road Rescue, agrees that safety is the most important facet in ambulance design. “We use a six-point belting system in forward facing seats because that’s the safest way to travel,” Schwartzbauer says. “The seats we use can swivel side to side and also slide fore and aft along a track.”

|

| (3) McCoy Miller built this medium duty ambulance for the St. Louis (MO) Fire Department with a sliding door so when attendants exit the vehicle, the door doesn’t extend far from the body, which is important if the ambulance is parked close to another vehicle or near the guardrail on the side of a road. (Photo courtesy of McCoy Miller.) |

Road Rescue also has begun using thermoplastics in the interior of the patient compartment. “Thermoplastic expands and contracts a bit more than aluminum, but it adheres very well to aluminum and is the same texture and color all the way through,” he notes. “The material is made in thickness comparable to a mica material, in the 0.035-inch range, so you can fold it in half and it will barely discolor. It’s also antimicrobial.”

Road Rescue is installing more biohazard containers in its rigs, Schwartzbauer points out, on the street side near the head of the patient, and forward and aft of the CPR seat. “We don’t want a medic to have to get up to dispose of sharps,” he adds.

Significant Impact

David Cole, vice president of sales for Horton Emergency Vehicles, agrees that the changes being brought by NFPA 1917 are the biggest trend affecting the ambulance industry in years. “We’ve worked continually to measure the G forces and integrity of the construction of our ambulances to demonstrate their safety,” Cole says. “We’ve worked with various test labs to improve our vehicles and use different materials to provide a higher level of safety.”

Cole says Horton has done both front- and side-impact testing to verify the sturdiness of its equipment mounting systems and redesigned its VITEC vibration isolation technology to produce a softer ride and better handling vehicle.

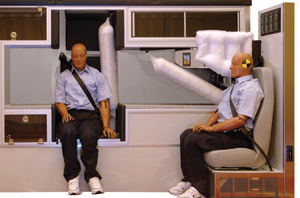

In 2009, Horton introduced the Horton Occupant Protection System (HOPS), an integrated system of seat belts, air bags, impact-resistant cushions, and rollover sensors designed to protect ambulance occupants. Cole says Horton is “working toward the next level of HOPS to provide safe impact zones, improved seat belt protection systems, and greater air bag protection.” HOPS is standard on all Horton ambulances, he notes.

|

| (4) Horton Emergency Vehicles installs the Horton Occupant Protection System (HOPS) in all its ambulances, an integrated system of seat belts, air bags, impact-resistant cushions, and rollover sensors that are designed to protect the occupants. (Photo courtesy of Horton Emergency Vehicles.) |

Cole says that Horton currently has about 60 percent of the medium duty ambulance market, chiefly vehicles with gross vehicle weight ratings (GVWR) of greater than 19,000 pounds, using chassis such as the Ford F-550, International TerraStar, and Freightliner M2. “The all-aluminum interior is unique to Horton,” Cole points out. “We do not have any issues of bloodborne pathogens that are associated with wood interiors. We also custom design our interiors for a safe work environment, putting the medics as close to the patient as possible, while still wearing their seat belts.”

Design Trends

Bob Parks, product manager for McCoy Miller, says his company has been installing more swivel seats in the back of ambulances. “The design around the seat has vacuum and oxygen outlets on both sides of the seat so the medic can access either one or both while belted in the seat without having to get up,” Parks says. “Dual switch panels, one on each side of the seat, also allow the attendant to operate the controls he needs without getting up.”

Parks notes that McCoy Miller has been installing more work stations in the back of ambulances. “Often they are a built-in tray with a slide-out drawer at the work station, with oxygen and suction on each side and a monitor at the top,” he says. “We’re also seeing more computer applications used in ambulances, and with electronics getting more sophisticated, you’re seeing road safety and engine monitoring systems being used.”

McCoy Miller builds many of its rigs on Ford F-550 chassis, although it recently has added Chevy, Freightliner M2, International TerraStar, and Dodge 3500 and 4500 chassis to its Type 1 ambulance designs.

“Other innovative things we’re looking at are the different types of building materials for cabinets and the ambulance interior,” Parks says. “At first, cabinets were made out of wood, and then aluminum and fiberglass. Now we use a composite material that is used in a lot of hospital cabinets.”

Inside the patient compartment, McCoy Miller has been using Sentra, a plastic-like composite board that has an aluminum exterior coating, making it impervious to liquids and chemicals. Parks notes, “It’s lighter than wood, is very durable, has very few seams, and is easy to clean.”

Schwartzbauer observes that many fire departments have been buying ambulances recently, so Road Rescue has been installing more roll-up doors on its ambulances (common in the fire service, he notes) instead of hinged doors.

Both Road Rescue and Wheeled Coach offer four-fan auxiliary air conditioning condensers that provide 30 percent more cooling capacity for the rigs. Both versions are fitted to the top front of the patient compartment and are able to mount seven vehicle warning lights-five across the front of the auxiliary unit and one on each side.

ALAN M. PETRILLO is a Tucson, Arizona-based freelance writer and is a member of the Fire Apparatus & Emergency Equipment editorial advisory board. He served 22 years with the Verdoy (NY) Fire Department, including in the position of chief.