The Cambridge Fire Department considered purchasing an electric vehicle (EV) pumper but didn’t have the necessary infrastructure to support such a vehicle, so it chose Pierce Manufacturing to build two traditional pumpers with short wheelbases, Pierce’s Idle Reduction Technology (IRT), and TAK-4 T3 all wheel steering.

Thomas Cahill, Cambridge’s fire chief, says the department ordered the two pumpers with IRT out of environmental concerns. “We have tight streets in Cambridge so we wanted to go with a smaller apparatus with a shorter wheelbase, but we also wanted to consider environmental issues,” Cahill points out. “We considered an electric vehicle pumper, but knew we didn’t have the infrastructure in any of our stations to support an EV, so we chose to go with pumpers that have Pierce’s IRT system.”

Cahill says that Cambridge has nine front line pumpers with three in reserve, and four front line aerials with one in reserve. He says that after getting the two new Pierce pumpers the department placed another order with Pierce for two additional identical pumpers.

The two twin Pierce pumpers for Cambridge are built on an Enforcer™ chassis and four-door cab with 304L stainless steel bodies, and galvanized frame rails and body substructures, TAK-4 T3 front and rear independent all steer suspensions, powered by a Cummins L9 engine and Allison 3000 EVS automatic transmission. The wheelbase on each rig is 181-1/2-inches, overall length is 29-1/2-inches, and overall height is 9 feet, 8 inches, with each pumper having a Waterous 1,250-gallons-per-minute (gpm) midship pump, and a 500-gallon water tank.

Nick Vertz, Pierce’s manager of business development for electrical and software technology, says Pierce has installed its IRT system on pumpers, aerials and rescues, but predominantly on pumpers. “Our system is designed to reduce the economic and environmental costs of a vehicle while it is idling,” Vertz points out.

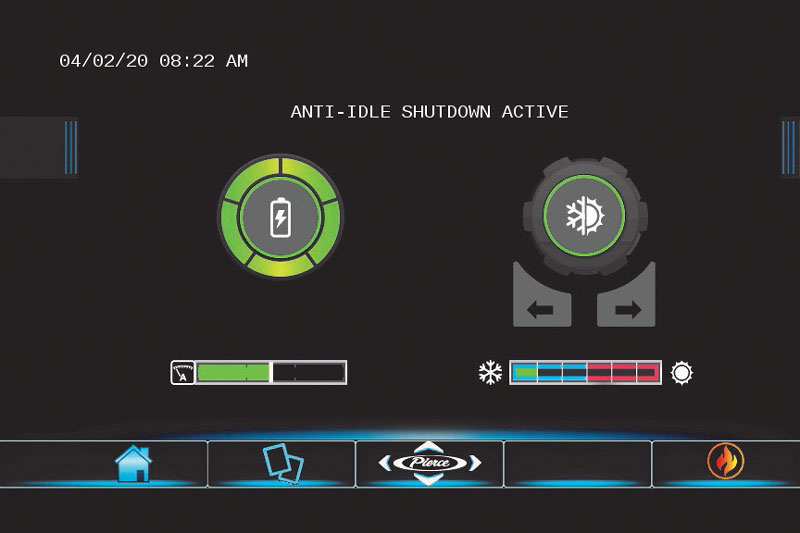

Vertz says Pierce’s IRT system on the Cambridge pumpers pairs automatic diesel engine controls with high performance lithium-ion and lead-acid batteries. He notes the IRT system powers all National Fire Protection Association (NFPA) 1901 required devices on the rigs, user-defined mission critical on-scene loads, and the heating ventilating and air conditioning (HVAC) climate control system with the main engine shut down with one hour of run time at 150 amps.

“The IRT system features built-in safety interlocks and Pierce Command Zone™ multiplexed electric system for auto-start for battery power monitoring and engine restart,” Vertz observes. He adds that the safety interlocks allow the automatic IRT system to activate when six conditions are satisfied for five minutes: the cab is lowered and locked, the battery and ignition are on, the vehicle is running, the pump is not engaged, the chassis parking brake is set, and the transmission is in neutral.

Vertz says that charging the batteries takes place through the chassis while the vehicle is operating, or from a dedicated 30-amp power source at the station. He adds that there are zero chassis emissions when operating under lithium-ion power, and that the efficiencies of the IRT system include less engine wear, lower fuel and DEF fluid usage, reduced soot buildup from idling, less frequent service intervals, and lower total cost of ownership.

ALAN M. PETRILLO is a Tucson, Arizona-based journalist, the author of three novels and five nonfiction books, and a member of the Fire Apparatus & Emergency Equipment Editorial Advisory Board. He served 22 years with the Verdoy (NY) Fire Department, including in the position of chief.