The COVID-19 pandemic changed a lot about FDIC International 2021, which, if you think about it, was a delayed 2020 conference.

It was still the largest conference/trade show in the United States since the pandemic hit, and there was every bit as much enthusiasm expressed by attendees and exhibitors alike. Many said it was the best FDIC ever because people had the time and, frankly, space to really engage in conversation and see the products being offered. There was a lot of excitement and enthusiasm for getting back to some sort of normalcy.

Since 1929, FDIC has been a forum for exchanging of all ideas and exhibition products for the fire service, and this year was no different. There were many never-before-seen items on the show floor including many items to keep firefighters safe from the unseen carcinogens on the firegrounds. On the other end of the spectrum, there were some products designed to help see the visible from the vantage point of overhead with drones buzzing the skies above.

It’s fair to say every single item in the Indiana Convention Center and nearby Lucas Oil Stadium was focused on making firefighters more efficient and their jobs safer.

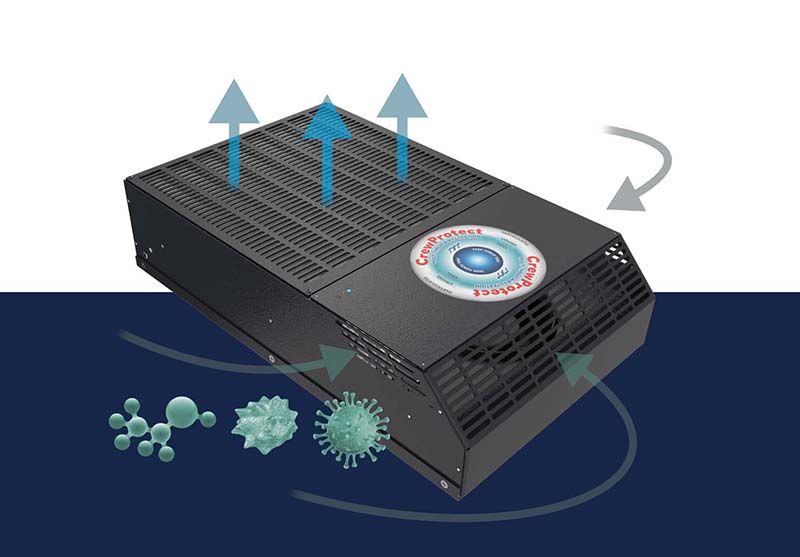

One of the things that caught my eyes was an apparatus cab filtration system offered by TFT called CrewProtect. It’s one of those things that is not as big, shiny, and sexy as a bright red fire truck on the show floor, but it can have a profound effect on the quality of life for firefighters. Sitting unobtrusively on a pedestal in TFT’s booth, this air filtration device quietly moved air through a Purafil Filtration Group filter removing particulates; VOCs; and aerosols carrying bacteria and viruses, including the virus that causes COVID-19.

Phil Gerace, senior vice president of sales and marketing for TFT, says the company was looking for a comprehensive but simple system to clean the air in apparatus cabs. What TFT came up with is a system that operates on 12 volts, installs with just a few bolts, and can be mounted anywhere in any position in the cab. It requires no external exhaust port. Gerace says the device filters the air in an average cab every 3½ minutes, which is a greater rate than that expected in a hospital operating room.

Will-Burt debuted a “Mobile Sentry Tethered Aerial System.” That’s kind of a fancy title for a drone. We all know Will-Burt as a light tower company, so to see a completely different kind of product was interesting. But, because Will-Burt is a lighting company, it shouldn’t surprise anyone that it was equipped with two powerful LED lamps producing 40,000 lumens, enough to light up the darkest scene to resemble daylight where deployed.

The Will-Burt representative demonstrating the product clicked through a variety of features on the new machine, using a touch screen control pad. The drone is fitted with a camera that can show normal images as well as infrared and thermal images.

The Mobile Sentry system can deliver video surveillance, communication, and illuminations up to 150 feet in the air. An option allows the drone to fly at heights up to 300 feet. It also has a four-hour battery run time.

When the show floor closed at 1 pm on Saturday, August 7, it left a mere eight months before the start of FDIC International 2022, and people can hardly wait. I’ll have to get in better shape to traverse the conference multiple times, as the next show promises to be bigger and better. Start making plans now to be there in April 2022.

Electric Apparatus, Specialized Rescue, Tracking Systems, Lighting Fixtures

By Alan M. Petrillo

Firefighters walking the exhibit hall floor at FDIC International 2021 got an eyeful of new technology, electric and traditional fire apparatus, fire/rescue boats, the prototype of a new firefighting tracking system, and new LED lighting fixtures.

Pierce Manufacturing promoted the Volterra, North America’s first electric fire engine that’s been in service at Madison (WI) Fire Department Station 8 for several months and has responded to more than 500 calls to date. The Volterra is built on a Pierce Enforcer™ chassis and cab with seating for six, powered by a 155-kilowatt hours (kWh) battery pack specially designed to meet Station 8’s daily duty cycle, and housed in an 18-inch-wide compartment at the rear of the cab.

Zeus Electric Chassis displayed a fully electric chassis/cab with a configurable wheelbase, battery capacity, and payload that uses existing OEM bodies and auxiliary tool functions. The rig has all-wheel-drive military-grade axles and independent suspension and a modular battery system that is scalable from 105 kWh to 420 kWh along with a thermal management system.

Unruh Fire introduced the Incident Stabilization Unit (ICU) on a Freightliner M2-160 4×2 crew cab and chassis with a 16-foot walk-through body. The unit is designed with a clean cab concept for minimization of contaminate exposure and maximum interior and exterior equipment storage options. ESI Apparatus Division showed its Xtreme Response Unit (XRU), an off-road rescue response vehicle designed by TOMARA available with a rear-mount gasoline, diesel, or electric engine.

At the W.S. Darley & Company booth, Darley displayed its ZSM 3,500-gallon-per-minute (gpm) industrial-rated pump, the slim TSM 2,000-gpm pump designed to fit an aerial’s tight spaces, and the LDMX 1,750-gpm pump that allows OEMs to design their own discharge manifolds.

Partnering with Darley was Ascent Integrated Tech, which showed its prototype Shield Platform, an augmented firefighters and incident command system that offers actionable insight to improve safety and effectiveness through a thermal imaging camera, mapping and location software, hands-free communication, firefighter heart rate monitor, environmental alerts, radio channel selection, and flashlight.

Another locating system displayed was MSA’s LUNAR, a small wireless, cloud-ready device designed to keep firefighters connected through person-to-person ranging, GPS locating, and personal thermal imaging and with a motion-detected man-down alarm. LUNAR can be used as a stand-alone device or as part of MSA’s G1 self-contained breathing apparatus (SCBA).

Lake Assault Boats, a division of Fraser Shipyards, showed a V-hull craft with a nine-foot beam that’s powered by twin Mercury four-stroke outboard motors for the Hennepin County (MN) Sheriff’s Office. The boat has a center console for maximum visibility, a foam collar to prevent hull damage, a portable fire pump aft with fixed discharge piping to the bow, and a portable monitor on the port side.

UPF displayed a new product—a Poly® hull water rescue craft that it plans to provide to OEMs to outfit with equipment to suit a customer’s needs.

Task Force Tips displayed its new Radius™ deck-mounted nozzle that’s often used for apparatus where below-deck extension tubes don’t fit; three versions of its Extend-A-Gun; and CrewProtect, a multithreat air filtration system for apparatus cabs powered by PuraShield.

IDEX debuted its SAM Smart Nozzle with N2P technology that puts elements of SAM’s pump control technology at the tip of a hoseline. Up to six handlines can be configured with a SAM Smart Nozzle on one apparatus.

In lighting, Will-Burt introduced Night Scan® Air, a portable 360-degree scene lighting unit that’s available in 24,000, 56,000, or 110,000 lumens, while FRC showed the Spectra Mobile portable LED light designed for rapid deployment and featuring a compact 15,000-lumens lamp head design, five light operational modes, and a plunging and hanging spike. FRC also displayed the remote control Ultrabright LED light that has 16 LED lights, which provide 7,000 lumens of brightness.

Attenuator for Roadway Safety

By Chris Daly

It was great to return to Indianapolis and teach the “Drive to Survive” program once again. I was pleased to see the amount of participation from our international firefighting community and look forward to FDIC 2022!

That said, as a member of the Fire Apparatus & Emergency Equipment editorial advisory board, I was once again tasked with roaming the show floor in search of some type of apparatus or equipment that jumped out at us. As usual, this year’s show did not disappoint.

I hail from the Philadelphia region and sadly, our firefighting community suffered a tragic loss just one week before the start of FDIC 2021. A nearby fire department suffered a line-of-duty death when a drunk driver drove into a crash scene on the Schuylkill Expressway, a major highway that connects the City of Philadelphia to the western suburbs. As a result of this tragedy, I set out to see what new equipment or apparatus may be available to prevent such tragedies in the future.

1 Photo courtesy of TFT.

2 Photo courtesy of Will-Burt.

5 Boise Mobile Equipment Type 3 wildland engine. (Photos 5-7 by Alan M. Petrillo.)

7 Unruh Fire’s Incident Stabilization Unit.

While roaming the rear parking lot of Lucas Oil Stadium, I came across a fire apparatus that was equipped with a “Scorpion II” truck-mounted attenuator. This device is manufactured by TrafFix Devices Inc., and the apparatus configuration was being marketed and sold by Gulf Highway Equipment from Haltom City, Texas. The apparatus and attenuator looked no different than a highway department vehicle that many of us have passed while driving through a roadway work zone.

The concept of an attenuator is simple: It is designed to absorb the kinetic energy of a striking vehicle and lengthen the “crash pulse” of the impact—the change in speed over a period of time. The greater the crash pulse, the more severe the crash and subsequent injuries. As an example, you may have flown to FDIC in a jet airplane. As you landed, you decelerated from 500 miles per hour (mph) to 0 mph, which is a significant difference in speed. However, this change in speed took place over 15 minutes as your airplane made its final approach into the airport and you suffered no injuries. On the other hand, a vehicle traveling 70 mph may strike the rear of a fire apparatus that is operating on a highway and decelerate from 70 mph to 0 mph in just a few milliseconds. As a result of this tremendous crash pulse, the crash and the subsequent injuries are often quite severe, if not fatal.

The purpose of an attenuator is to provide a longer period of time for a striking vehicle to “ride down” the crash and come to a stop. As the attenuator buckles, collapses, and absorbs the kinetic energy of the striking vehicle, it extends the time it takes for the vehicle to come to a stop. By lengthening the crash pulse, the impact is “softened,” lessening the severity of the impact and the subsequent injuries to everyone involved. This is a simple yet effective way of protecting both the emergency workers on the scene and the occupants of the striking vehicle.

I would argue that it is time to start equipping every apparatus that responds to a highway with a traffic attenuator just like every highway department crew operating on the roadway brings an attenuator

8

9

10

11

12 (Photos 8, 9, 10, 11, 12 by Chris Daly)

truck (or several) along with them to protect themselves on the road. Aren’t we in the same situation? Is it time to rethink our rescue trucks and have a specific type of highway rescue truck vs. confined space or industrial rescue trucks? How about highway engines that respond to vehicle fires? While I realize this is a bold concept, the number of emergency responders struck on the road every year certainly justifies the conversation. A fire apparatus with an attenuator mounted to the rear of it will significantly increase the safety of both the crews operating on a highway and the motorist who may drive into the stopped fire apparatus with an attenuator mounted on the back.

To see a fire apparatus equipped with a traffic attenuator may seem strange. Many of our young hotshots may not like the look of a vehicle equipped with such a device, but it’s not about appearance—it’s about safety and functionality. There was a time when firefighters thought that a fire truck with a giant ladder mounted on the top or a huge water tank mounted on the body looked strange and silly. How did that work out for our profession?

On a side note, now that I’m an old guy, I have to ask: What’s up with the infatuation with black painted rims and wheels all of a sudden? I’m a chrome guy through and through.

Firefighter Health and Safety

By Richard Marinucci

Summer school. When I was a kid, this was dreaded. It was intended for those who failed a class or were falling behind for some reason. It would ruin your summer. But, with my children today, it could be an opportunity to get ahead. That is what Summer School with FDIC was in 2021. The pandemic stopped a lot of training and conferences. Much was lost. The good folks at FDIC couldn’t wait until April 2022 to get firefighters back on track and held a great conference.

The similarities to the “normal” FDIC were everywhere—from the well-produced general sessions to the variety of preconference workshops and H.O.T. classes to the large number of vendors on display. It was impossible to partake in everything that was offered. Those who attend need a plan and need to focus on their particular interests. As always, there are overriding themes and the conference provides insight into the state of the fire service and what can be expected in the future. The products and services on display are definitely part of it.

In my opinion, the products and services being touted were about battery power, lightweight, using more technology, and firefighter health and safety. This would apply to the larger companies and the upstarts. This is logical and reflects society as a whole. Think about your life outside your department. All of these are around us and representative. It should be no surprise.

The tools that firefighters use are becoming lighter and battery-powered. This is a good thing—fewer obstacles to work around, easier use, less fuel to store and carry on apparatus, and more compartment space to add items needed for the ever-increasing job duties. Certainly, all departments need to develop a plan to transition, as the new tools will offer greater flexibility, ease of use, and space. It is hard to find fault with any of this and will only improve service.

Technology was on exhibit everywhere. It touched all aspects from the big rigs to the various appliances needed to provide efficient and effective service. This will expand the capabilities of those who embrace it and learn the benefits. FDIC 2021 offered a one-stop shop to explore the possibilities. The vendors did all they could to provide the details and information. In many ways, it is overwhelming but ultimately will transform various aspects of the fire service in a positive manner.

Firefighter health and safety remains on the front burner. Regardless of the motive, there was no denying that the wellness of firefighters is part of everyone’s business. Even with discussions and debates on aggressive firefighting, commitment to serving the public, and other related topics, the people providing goods and services want to help keep firefighters safe and healthy while doing their job in a manner that has become part of the culture since the beginning of fire departments. There were products to help locate firefighters lost or in a Mayday situation, others offering ways to deliver air when the cylinders emptied, and health and wellness topics. The importance of offering ways to minimize unnecessary risk, provide redundancy for safety, and offer options in cases where things go wrong was on display. There seems to be a good effort being made to balance the dangers within the job with methods to weed out dangers that don’t affect the ability to do the job that firefighters are sworn to do.

Apparatus on Display

By Bill Adams

This report encompasses only the apparatus displayed. There is no priority in the features observed nor favoritism shown; hence, manufacturers’ names are omitted. My commentary reflects personal opinion only and is not necessarily reflective of industry trends. The apparatus displayed were likely only those available at showtime.

Tractor-drawn aerial ladders (aka tillers or TDAs) displayed different ground ladder storage. One featured doubled banked horizontal ladder storage that slides out the rear. Others stored and slid ladders out the rear on their beams. Interestingly, most pumpers also featured rear slide-in ladder storage either horizontally or on their beams. Why the difference? One TDA also had ladders hanging on each side, indicating ladder accessibility is a priority.

13

15 (Photos 13, 14, 15 by Bill Adams)

Most towers, platforms, and aerials—including the TDAs—featured pumps and tanks. The 75-foot aerials’ popularity has been surpassed by 100-foot devices now available on a single rear axle. One wonders why a purchasing committee will demand a single-axled quint, only to park it next to a rescue truck that’s higher and has a longer wheelbase, a larger turning radius, and often a dual rear axle.

It appeared there were more large heavy rescues than medium and light duty styles. Equipment mounting in the compartments did not appear as “cramped and crowded” as in past years.

Pumpers featured a wide variety of front bumper discharges and hose storage configurations. Apparatus purchasing committees are wise to use diligence in specifying such an expensive option.

Many pumpers and pumper-tankers featured “real” access ladders at the rear to access hosebeds. Regardless of the actual configuration, they are safer and easier to use than small access steps.

Many apparatus designs seem to be more multifunctional, with layouts appearing more usable for limited staffing. Many manufacturers displayed “wildland” type apparatus.

Regardless of if located on the face of high-side compartments or on the backs of the cabs, flip-down access steps at midship pump panels are dangerous. The operator’s panel is a busy place that doesn’t need firefighters acting like rock climbers scaling a wall to access the top of the pump house. It interferes with pump operation at the least and is a fall hazard at the most. Most apparatus had them.

It looked like many rigs were lacking in “grab handles” to facilitate accessing the top of the rigs. Remember, if they are not called for in your purchasing specifications, they do not exist and you might not get them.

Mini-Survey: A dozen “custom pumper” single-page spec sheets were randomly collected from a half dozen manufacturers. The intent here is to give a brief snapshot of what’s being purchased and offered. Five were demo rigs and seven were sold. Eight had 1,500-gpm pumps, and there were two each 2,000 and 2,250 gpm. Four had 500-gallon tanks; two had 750- and six had 1,000-gallon tanks. All but two had some sort of onboard foam system with tanks. Eleven had raised roofs. Ten had high side compartments on both sides with rear slide-in ladder storage. Most featured a variation of a “medium” four-door cab with five or six seats. All 12 had extended front bumpers, but only half had front 6-inch steamer connections. One had nothing at all on its bumper. All but one featured side-mounted pump operator panels. Seven rigs were painted all red, two were black over red, one was gray over orange, one was gray over lime-green, and one was painted all white. Only three claimed to have a “low hosebed”–one at 60 inches, one at 65 inches, and one didn’t say but looked around 6-foot from ground level.

Many apparatus manufacturers said business is good and they are looking to expand and hire help. There were a lot of dealers and salespeople in attendance. Apparatus manufacturers seem to be leaning toward “mega” dealerships throughout the country. I got a kick out of the obvious purchasing committees in attendance—usually one person acting as a scribe, several younger ones asking plenty of questions and taking lots of photos and videos, and one or two older members riding herd. They picked a good show to look at fire trucks and compare them.

Virtual Reality and More

by Robert Tutterow

FDIC 2021 did not lack new product introductions and adaptations of existing products. Learning about them was invigorating. It was great to see the fire service “re-gather” in person again and see acquaintances for the first time in more than two years.

Two product introductions really stood out to me. First, Viking Life-Safety Equipment introduced the first tri-level certified personal protective equipment (PPE) coats and trousers that are suitable for all nonstructural fire responses. The lightweight set is certified to National Fire Protection Association (NFPA) 1951, Standard on Protective Ensembles for Technical Rescue Incidents; NFPA 1977, Standard on Protective Clothing and Equipment for Wildland Fire Fighting; and NFPA 1999, Standard on Protective Clothing and Ensembles for Emergency Medical Operations. By using this type of garment, firefighters can get away from the bad practice of wearing their structural PPE to every type of call. Many firefighters don their structural gear regardless of the nature of the call. This leads to undue heat stress and cross-contamination to the public we serve. Some fire departments may reexamine their risk assessment and decide that a set of tri-certified gear is better than a second set of turnout gear. Ideally, firefighters should have both a second set of turnout gear as well as tri-certified gear. The tri-certified gear is much lighter (no thermal barrier) and costs about 25% less than a set of structural gear.

16 Darley’s FLAIM Trainer (Photos 16, 17, 18 by Robert Tutterow)

17 CO2 PPE cleaning machine from LION TotalCare.

18 Rosenbauer’s robot.

The second new product that made a big impression on me was FLAIM Trainer. This product was being demonstrated in the W.S. Darley booth. It is a virtual training tool for live fire training in a 3D reality environment. The product has been in development for 10 years and, though prototypes have been at previous FDICs, this year it was being formally introduced as market ready. I was fortunate enough to participate in a demo of the product. I was equipped with a virtual reality headset with built-in SCBA sensor technology. I donned a vest to simulate the wearing of an SCBA. The vest was like a high-tech electric blanket in that I was able to feel the heat. The fire extinguishment was accomplished by a TFT nozzle that had embedded high technology that allowed for nozzle reaction as well as water flow pattern control. The experience was amazingly realistic as I virtually moved through a house that had a fire in the kitchen. The imagery was incredibly real. On completion of the scenario, I felt like I had moved about the fire structure while experiencing the same environment as in an actual fire but, in reality, I had only stood and moved about a couple of steps in a booth on the FDIC exhibition floor. With the difficulty of finding structures to burn and live fire training forbidden in some areas, this product is a very valuable tool for training firefighters.

Two other products made an impression on me. One was the MSA “LUNAR.” It provides thermal imaging with direction and distance and personal thermal imaging to greatly improve situational awareness, and it connects everyone on the emergency scene. The other product was a CO2 PPE cleaning machine from LION TotalCare. Though it is a piece of equipment not affordable for most departments ($500,000), departments can send their PPE to LION TotalCare and get the most advanced cleaning on the market. It is far superior to traditional or ozone cleaning. The machine is large in that it is between 10 and 12 feet tall. It requires no drying time, nor does it use water.

Other notable new products included a robot from Rosenbauer. The machine was very adaptable with different modules available to place on the rubber-tracked chassis. These included a master stream nozzle, cameras, flatbed hauling and grid-box hauling, an equipment carrier, and lighting. Rosenbauer also displayed the Boros B4 with its Quick-Release fastener system and Michelin soles. Hopefully, this will become NFPA-compliant soon.

Extractaire was showing a 3-stage apparatus cab air filtration system that used activated charcoal. The unit is available to any apparatus manufacturer and is retrofittable to existing apparatus.

In addition to this sampling of new products, I was fortunate enough to get a glimpse at some products in the design stage that hopefully will be introduced at FDIC 2022.

The RescueONE® WATERBot™

By Raul Angulo

This year’s FDIC was well-attended. There is always something for everyone and again, the innovation in firefighting and rescue equipment did not disappoint me. My fire service career started in the U.S. Coast Guard. In addition to marine shipboard firefighting training, I was also a rescue swimmer before the official Class A school was even formulated. Throughout my career, I’ve always had an eye out for water rescue equipment. The RescueONE® WATERBot™ is a manually operated or remote-controlled self-righting intelligent lifebuoy flotation appliance that can be used in all types of water rescue incidents, including salt water, fresh water, swift water, and flood rescue work.

RescueONE® was originally founded by Tony Lumpkin as a subdivision of the MarineONE Corporation, which is primarily known for Connector Boats, used by emergency response teams worldwide, so it is only logical that this company would recognize the rescue need and manufacture such an innovative life-saving product.

The WATERBot (water robot) is a horseshoe-shaped lifebuoy similar to the torpedoes many lifeguards use at public beaches and lakes. The horseshoe shape offers greater stability, and its buoyancy is equivalent to four life rings. The international orange 31-pound unit measures 38 inches in length × 30 inches in width. The twin motors and propellers are powered by a lithium-ion battery that provides 60 minutes of propulsion power. The motors are shrouded with a protective grille to protect the rescuer or victims from the spinning propellers. The unit has a built-in Human-Detection Module that shuts down the motors when the WATERBot comes within 15 inches of the victim. The bow has a durable but soft rubber bumper to protect victims from being struct by the WATERBot as it approaches.

The unit has a self-righting antiturnover design, which means if it lands in the water upside down or flips over in a wave or strong currents, its strong buoyancy

19

22 (Photos 19, 20, 21, 22 by Raul Angulo)

and double propellers will flip the unit upright so it can continue. This means the WATERBot can be used in choppy water and bad or inclement weather.

According to the Centers for Disease Control (CDC), there are 4,000 drownings in the United States—an average of 10 per day. Worldwide drownings are @ 360,000. So, time is of the essence. WATERBot unweighted can travel 15 mph or 27 feet per second. In the manual mode, the rescuer rides the WATERBot to the victim. A rescuer weighing 200 pounds will reduce the speed to approximately half, or 15 feet per second. The control buttons are in the thumb position next to the handles. The right handle has the acceleration button and the turn to starboard button. The left handle has the deceleration button and the turn to port button. The rescuer can bring any equipment or rope that can be clipped onto his person. The rescuer can easily tow one or two victims. Variables like wind and current will affect the speed, but the unit is capable of towing two victims plus the rescuer or perhaps even more. Slow going is better than no going, and a rescue swimmer can usually only rescue one person at a time.

Rapid Rescue in the Remote Control Mode. In this evolution, the rescuer can throw the WATERBot off a bridge or a dock or launch it from shore. No special throwing techniques are required. If the appliance lands upside down, the self-righting antiturnover design will right the buoy so it’s ready to sail. The WATERBot in remote control mode has a signal range of 5,000 feet. When the buoy comes within 15 inches of the victim, the motors will stop. Using GPS, there is a One-Key Return feature, a One-Route Return feature, and a Signal-Losing Return feature, all of which, with the push of a button or a lost signal, will return the WATERBot back from where it was launched. A conscious victim merely needs to hold onto the handles and ride the WATERBot back to shore. This is the fastest evolution I can think of for the first-arriving unit without the logistics required to launch a boat or a jet ski.

Traditional Water Rescue. Consider the traditional water rescue logistics that come into play when a call comes in for a person in the water. For fire stations equipped with boats or jet skis, the trailer will need to be hooked up to a truck and respond to the boat launch. There may be only one boat for citywide coverage, which may include multiple bodies of water. In addition to the response time, depending on where the victim is in relation to the boat launch, additional time becomes a serious factor. The WATERBot is compact enough that it can be carried on every fire apparatus instead of life rings or torpedoes. The fire engine can respond to the shoreline closest to the victim and launch the WATERBot. Considering the cost of maintenance and fuel for small boats, including the trailers, the cost savings to accomplish the objective of rescuing a person who may be drowning are obvious.

Throwing a life ring requires strength, coordination, and practice for accuracy. But no matter how well rescuers throw a life ring, they can’t throw it 5,000 feet; and, if it’s tethered, it’s limited by the length of the rope. Rescue swimmers can become fatigued depending on how far they have to swim, whether they’re battling winds and currents, and if they have to endure cold water temperatures. But no matter how strong or fast a rescue swimmer is, even with fins, no one can swim 15 mph or 27 feet per second!

The WATERBot comes with a spare lithium-ion battery, a charging unit, and a carrying case. The unit retails for approximately $7,900.00.

Bold and Brave New Renaissance

By Carl J. Haddon

In retrospect, FDIC 2021 as a whole offered much more to the future of the American fire service than I expected in light of these post-pandemic times. My two “focused areas” of attention, if you will (To the Rescue and Rurally Speaking columns), are on technical rescue and rural fire department issues and concerns. Overall, I was pleased with the number of rescue-based products and programs offered in the educational offerings as well as on the trade show floor.

Presenters offered methods and tactics that allowed us to increase our awareness and defenses of occupational exposures and hazards. Vendors seemed to offer goods and services that allowed us more of an opportunity to protect ourselves while we knowingly sacrifice ourselves and our well-being for the sake of others that we serve. Everything from advances in PPE fabrics with toxin barriers to firefighting agents to lessen our exposure to toxic smoke and byproducts of combustion to new on scene decontamination products that allow us to minimize the bad stuff that is absorbed through our exposed skin were on display at FDIC 2021.

In addition to the educational component and commercially available goods and services to prolong our existence, I saw a great number of products on display that help to allow us firefighters to be good stewards of our environment. Products that caught my eye and attention are those that offered solutions to the PFOA and PFOS issues caused by traditional firefighting foams. I also noticed a number of companies and manufacturers that have, and plan to continue to expand, their rescue product lines. Everything from advances in drysuit technology to handheld adjuncts and tools was on display and certainly caught my eye.

Finally, seeing advances in hydraulic and battery powered rescue tools that seem to offer continuing hope for better success in tackling ultra high strength metals and alloys found in today’s new vehicles was more than encouraging.

Overall, I saw this FDIC as a bold and brave renaissance event for attendees, promoters, advertisers, and manufacturers represented in Indianapolis. Personally and professionally, I look forward to getting on with our “new normal” and continuing the exploration into products and technology that help us to do a better and more efficient job while minimizing our exposures to the hazards that we are facing on a daily basis while we go about our chosen profession.

It Has Been a While!

By Ron Heal

Yes, it has been a while between the 2019 April conference and our gathering for the August 2021 conference in Indianapolis. So much has happened in the world as we deal with all the forms of COVID. Many questions were on our minds. How many vendors would be on hand? How many emergency services personnel would attend? How had apparatus manufacturers both large and small weathered the past two years? With international travel at a standstill, attendance was still impressive considering all the COVID issues. All things considered, this was the largest conference at the Indiana Convention Center and Lucas Oil Stadium in two years. Apparatus manufacturers both large and regional shared what they had managed to keep in production and, going forward, two main concerns will be obtaining component parts and having enough experienced workers. One regional manufacturer shared that her company had the best sales numbers on record. Several manufacturers felt that the industry could see a quick recovery in the balance of 2021 and 2022. Don’t look now, but FDIC 2022 is only a few months away.

In a Fire Apparatus & Emergency Equipment Advisory Board meeting, the topic of robots in the fire service came up. Robots as firefighters is a fairly new concept. Rosenbauer was displaying its RTE Robot 800 that is built in Europe. This unit is a radio-controlled, electric-driven, multifunctional tracked vehicle. For firefighting, a pumping model can flow 1,000 gpm @ 145 psi.

In Lucas Oil Stadium, Howe & Howe displayed the THERMITE™ RS3. Built in Maine, the firefighting unit resembles a tank with a flow rate of up to 2,500 gpm. This model has a list of several options, including a V-shaped tractor blade that can push aside items in the path of the unit. Robotics Program Manager Paul Ford advised that several Model RS3 and RS1 are in service worldwide, primarily with military installations.

A few years ago at FDIC, Rosenbauer introduced a concept electric fire engine. At that time, they stressed that this was strictly a concept fire engine and there were no plans for production. Fast forward to this year’s conference, and Rosenbauer has several customer orders for the RT pumpers. Electric fire trucks appear to be the future. For some, the future is now. Pierce is introducing the Volterra™ platform of electric vehicles, reducing emissions, minimizing fuel consumption, and producing less noise. Currently the Madison (WI) Fire Department is running a Volterra™ pumper as Engine 8. Driving, pumping, and charging operations are being evaluated on a daily basis by Pierce.

In the large parking lot next to the Convention Center, there were several hands-on working displays. IDEX Fire & Safety operated the SAM system, an integrated total waterflow control system that manages the fire engine’s pump, tank intakes, and discharges from a touch screen display. Complex pump operations are made simple. A few years back, inventor Jason Cerrano was showing his system on a loaned pumper. Now Jason is a part of the IDEX team and new orders for apparatus are coming through with the SAM system as optional equipment on new rigs. Jason shared that his best-selling tool has and continues to be satisfied customers that are spreading the word. Some customers were very skeptical of the SAM system but once it is in service they see the ease of pump operations.

A visit with Paul Christianson, Ferrara aerial specialist, a part of the REV Group, pointed out their World of Innovation and Protection exhibit that featured ECO-IDLE-TEC, Smart Flo, Smart Reach, Multi-Stance, and Active Air Purification System all designed to give operator safety and ease of operation to firefighting.

We continue to be in a very changing world on several fronts. FDIC will continue to be a leader in firefighting and emergency services training and exhibits. I look forward to FDIC 2022.

Innovation on Display at Innovative Controls

By Bill Peters

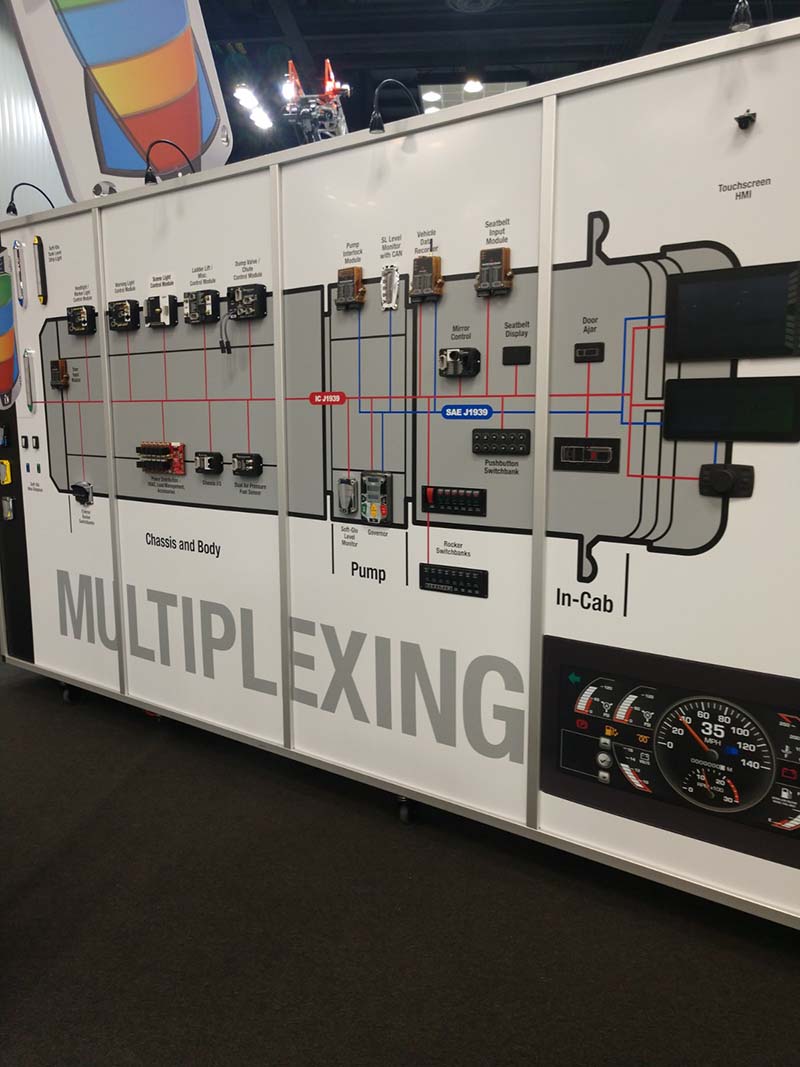

Many, many moons ago, I attended an apparatus symposium, and one of the speakers addressed a new electrical system called “Multiplexing.” He explained how a centralized computer would receive commands from nonloadbearing switches and send the commands down a pair of narrow wires to control modules that would command lights to turn on or off or control other accessories. He explained that the system could be configured to do almost anything that we wanted such as having remote lighting switches at the pump panel or at the rear of the truck. The only power wires would be feeding the control module. No more burned-out headlight and warning light switches on the dashboard from overloads, and the giant coils of wiring harnesses that ran all over the truck would be cut down considerably.

Controlling the functions of the truck this way seemed farfetched at the time, but he informed the audience that the first multiplexing would be used with the engine/transmission combination. He was right. On diesel engines, we went from mechanical accelerator linkage using rods and springs and mechanical vernier throttle controls on the pump panel to those functions being controlled by variable electrical switches. As time went on, we found more and more functions on the fire apparatus being controlled this way including pressure governors, electrical load managers, limit controls for aerial ladders to keep them out of trouble, and digital touch screen pump panels and dashboards. The future is here.

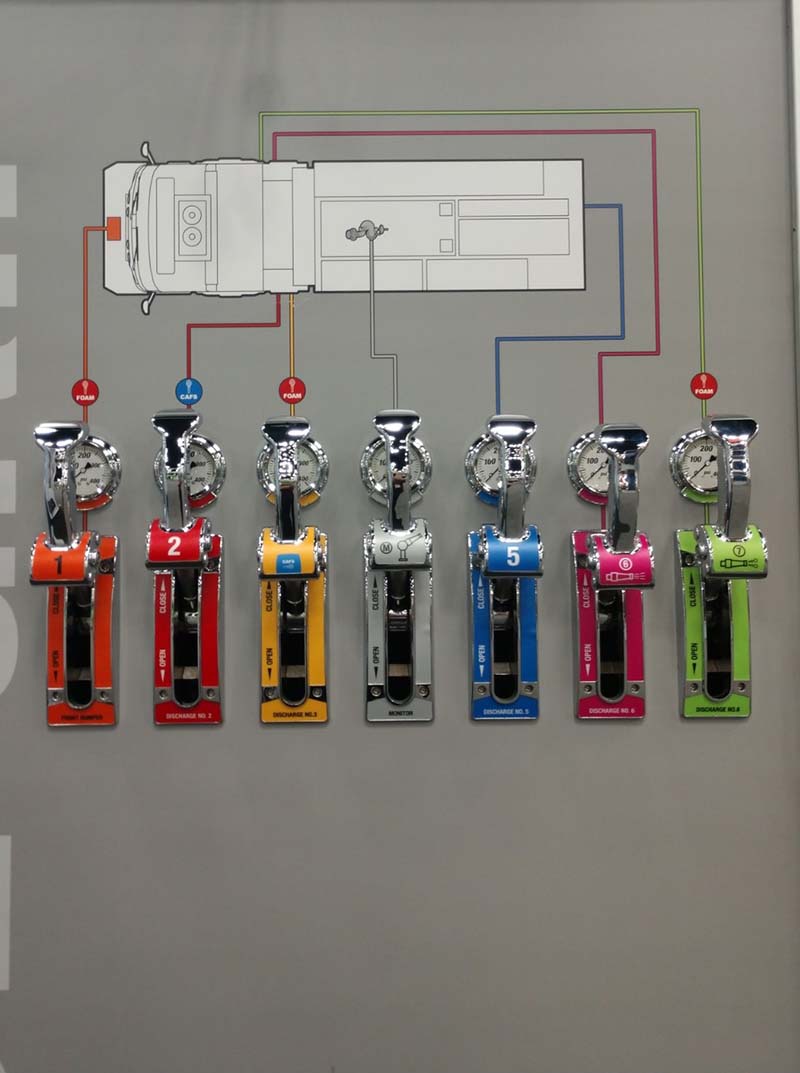

The understanding of how this system laid out on a fire truck was made easy by Innovative Controls at its FDIC International 2021 display. A whole wall with the actual multiplexing components at their various locations around the apparatus was on display, making it easier to understand (photo 23).

Another display of scene lighting controls with switching in the cab, both sides, and rear allowed you to turn the lights on and off from the various locations (photo 24). Digital dashboards were also shown in this display.

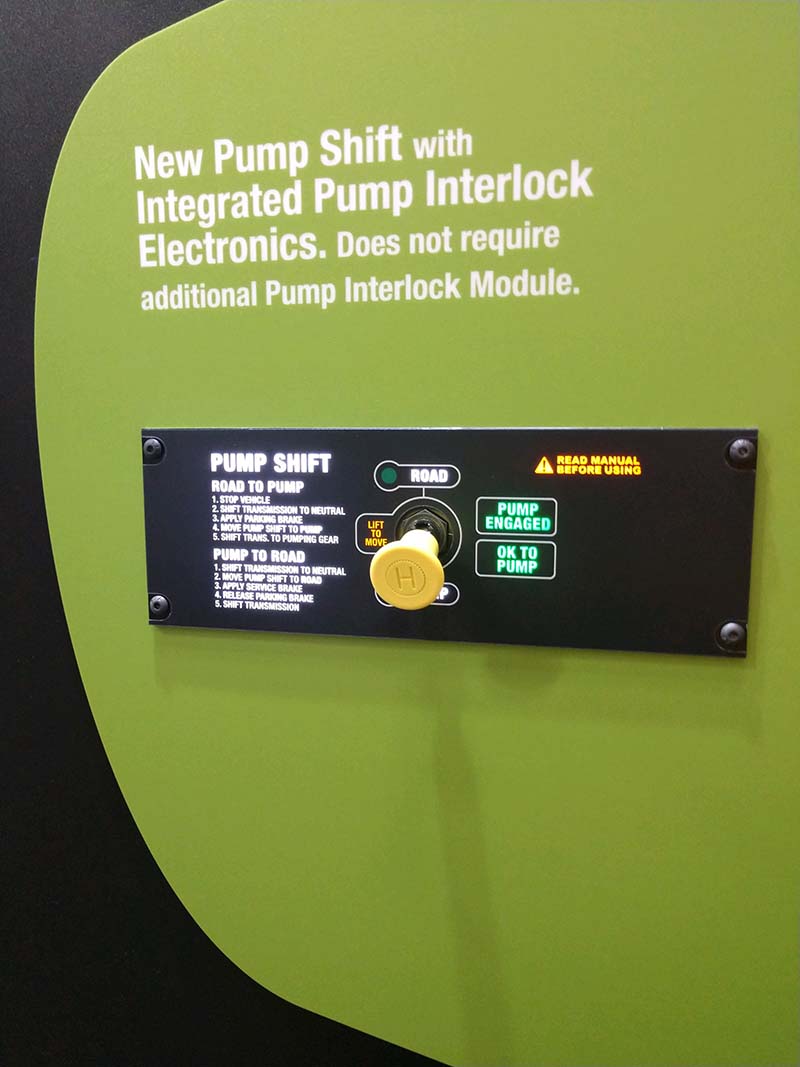

Another display that I found to be interesting was the electronic pump shift control with interlock. While it looked like any ordinary pump shift, the big difference was that the instruction plate was back-lit (photo 25). I once testified in a lawsuit involving a pumper “runaway,” and one of the questions asked was if the driver was able to read the correct pump-shift sequence in the dark. NFPA 1901 calls for all controls to be illuminated, which is something that I have faithfully verified during factory inspections. Many are not.

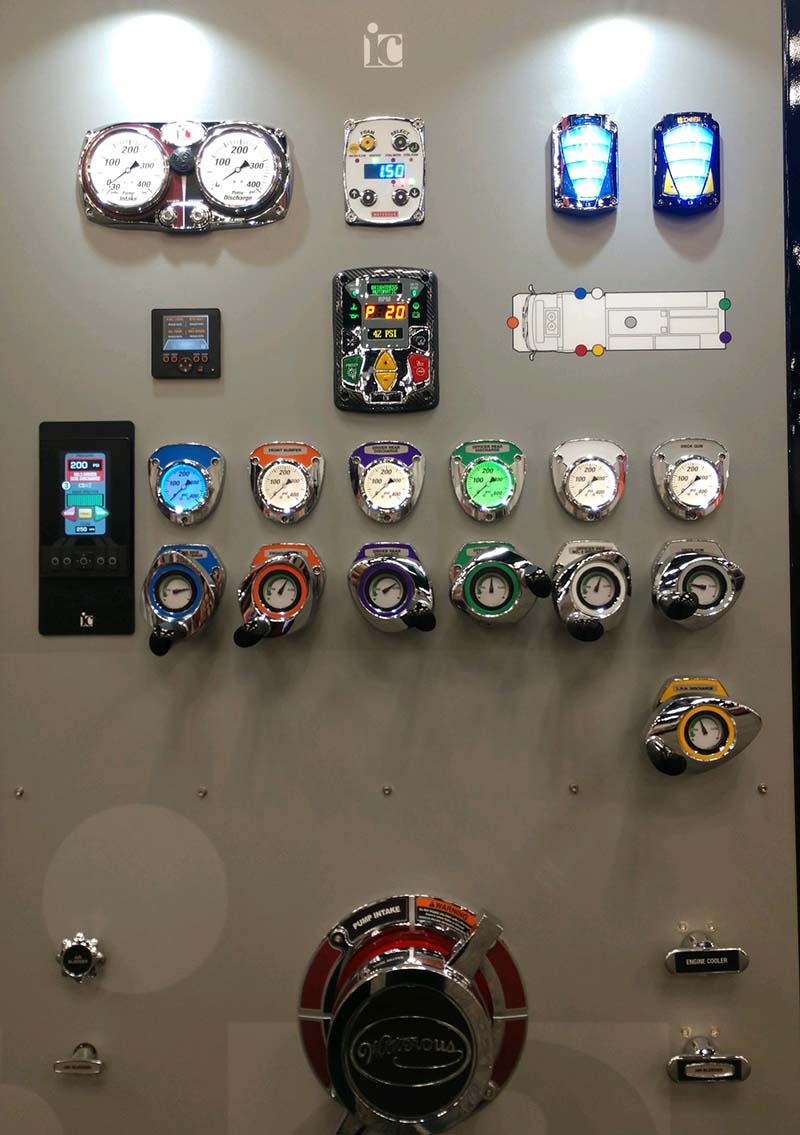

A full display pump panel with pressure governor, compressed-air foam controller, water and foam level gauges, color coded and color back-lit gauges, as well as handwheel valve controls was shown (photo 26). Other

28 (Photos 23, 24, 25, 26, 27, 28 by Bill Peters)

mechanical lever controls for both top and side-mount pump panels look a lot easier to operate and control than routine push-pull rods (photo 27).

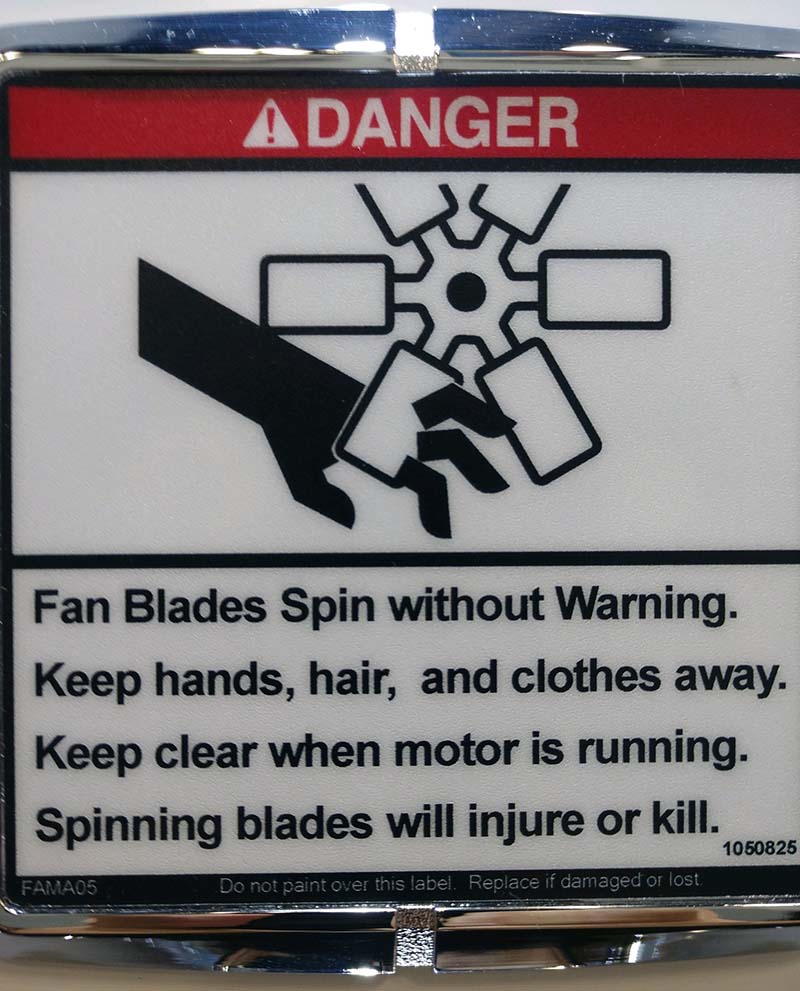

Everything from illuminated folding steps, FAMA warning labels (photo 28), lever drain valves, seat belt and door-ajar displays, and various remote tank level indicators were all on display. Innovative Controls certainly is innovative with its products.

Advances in Ladder, Brake Technology

By Ricky Riley

Watching the social media feeds prior to the show of the rigs heading into the show gave us a glimpse of what we were going to see once we arrived. The manufacturers brought their best and, once out in Indy and on the show floor, we were not disappointed. The apparatus booths had plenty of rigs to gawk over and admire the engineering, craftsmanship, and options chosen by the departments to serve their communities. Every rig was displayed with pride by the builder and showed the diverse needs of our fire service across the country.

One of the unique things I saw at a booth was a display of an in-service ladder truck from my home state of Maryland. The rig had been in service for a while and was brought out to Indy for display. Along with the rig, the department had personnel there at the booth to help answer questions about why they did what they did in designing their truck. This gave the people interested in the “why”s a direct answer from the end user rather than a salesperson. And, of course, it is always great to see the pride in the department members when they are discussing their rig and showcasing its features.

32 (Photos 29, 30, 31, 32 by Ricky Riley)

One of my personnel favorites regardless of manufacturer is the resurgence of the tiller truck purchases across the country. These rigs were usually reserved for the big city or metro departments, but that has changed as departments see the operational features and the exceptional ability to store equipment and a large number of ground ladders. There was a number of them on display from different builders, all with designs and engineering that made each of them unique.

Of course, nothing says unique like having wooden ladders on your apparatus. They look absolutely stunning and for that department provide the operational function needed for its response area.

Another item of note on that rig was the roller system. This system, in the rear ladder bed, helps slide the ladders in and out of their storage slot. It’s nice to see departments making it easy to get the ground ladders in and out.

It was interesting to see the advances in ladder technology and reduction of ladder weight that now allows for 100-foot-plus ladder trucks to have a single axle like back in the day. There were a number of them on display, and their small, compact size would provide great operational ability on many firegrounds in my area. Small footprint and fast setup are two great attributes to have in a straight ladder truck. In my experiences, we always like a lot of brakes—hence, a lot of tandem axle rigs. Brake technology and the ability for brakes to cool themselves and provide good braking for these weights have advanced as well.

I was fortunate enough to be able to spend two days on the showroom floor and still did not get to see everything and talk to everyone I wanted to spend time with. It was phenomenal to be able to see people in person and to talk to them face to face and not through Zoom or any other computer program. I look forward to eight months from now when we will all get back together in Indy with fresh new rigs, new equipment, and new designs.