John Burkhart

Director of Sales and Marketing Snap-tite Hose

CM: Can you give me a brief history of Snap-tite Hose?

JB: Our history really shows innovation in any industry we are or have been in. We brought the first large-diameter hose (LDH) to the market in 1980; we perfected the technology for extruded thru-the-weave nitrile rubber hose products in 1988, brought versatile well-known names in the hose industry under one roof in the 1990s, gained our ISO certification in the early 1990s that is still maintained to this day, added even bigger LDH to the market in early 2010, and the list goes on. Snap-tite Hose went back to the roots of who we are as a company by going back to the trusted name in 2020. This was because people know and deeply trust who we are and what we stand for under the Snap-tite Hose name. We still manufacture our products in Pennsylvania, just like we did more than 50 years ago. We wanted to make sure everyone knows that we stand for tradition while also striving for innovation to make the industry safer and make people’s jobs easier whenever possible.

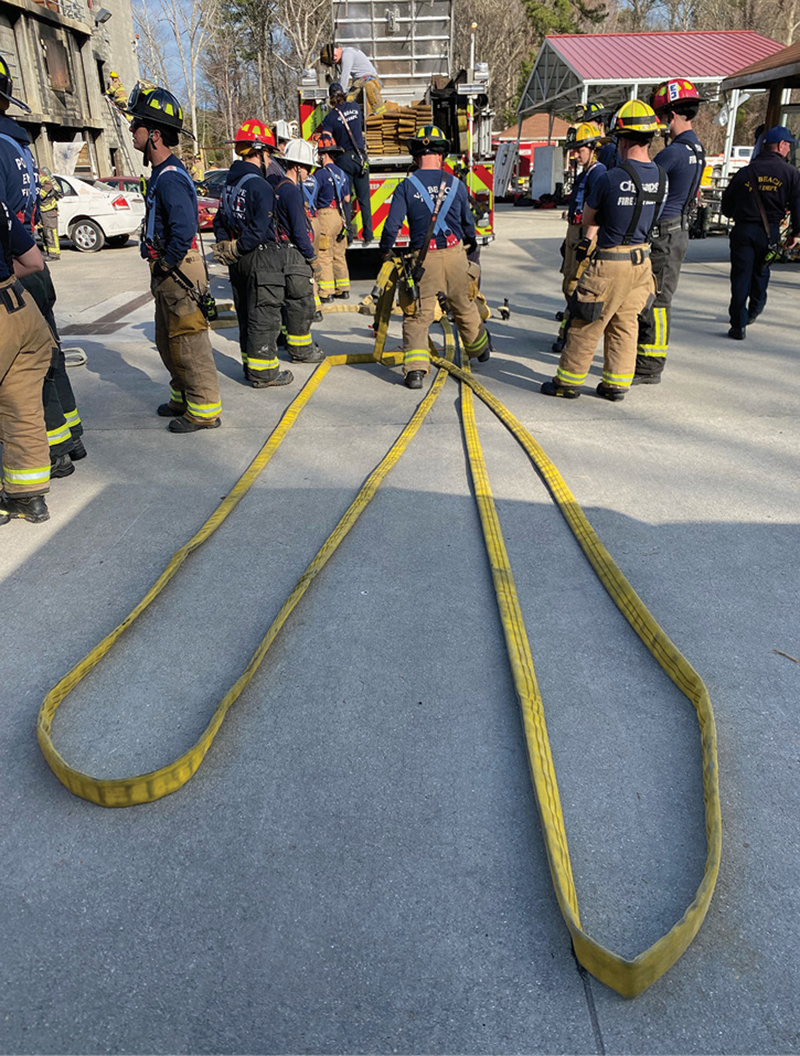

1 Photos courtesy of Snap-tite Hose.

CM: What is your newest product?

JB: The Snap-tite Hose Warrior. It changes the whole dynamic, and we now have a product that will go 40 to 50 minutes under huge duress; it’s a game changer. It’s in a class all its own. The Snap-tite Warrior is 70 times stronger than traditional polyester or nylon jacketed hoses. It is far more puncture resistant and cut resistant as shown in laboratory testing, where it has gone over 91,000 tabor abrasion cycles before failing. This hose will change the dynamic of how the industry perceives fire hose. The old thinking was that “hose is just hose,” but with today’s fires burning hotter and spreading faster, the hose manufacturers have to step up and answer the call for a better heat-resistant, abrasion-resistant, and puncture-resistant fire hose. Snap-tite Hose has answered this call to action. Try the Warrior and you will see; this is the next generation and is the future of fire hose as we know it today.

2

CM: What are the current trends in hose design?

JB: Longer lasting, kink-resistant, performs well at low pressure, packs well, puncture- and heat-resistant—this is what led us to designing the Warrior using para-aramid fibers.

CM: How should fire departments plan their truck specs around the hose they choose for the rigs?

JB: They need to consider their water hydraulics standard operating procedures and the types of fires they are dispatched to—meaning, are they using low-pressure, mid-pressure, or high-pressure nozzles? What types of fires are they primarily fighting (brush fires, car fires, structure fires, etc.)? This leads to demographics (do they live in a rural area or urban; do they have an interstate running through their backyard?).

CM: What keeps you up at night and why?

JB: The thought that we could have helped to save someone’s life by supplying them with the proper equipment. Try as we may, some departments simply do not have a budget that can afford the best of the best. We try to supply quality in everything we make so that the firefighter can safely rely on our products and go home safe after a fire. It is our job to make sure they have the opportunity to have the best equipment out today. It is theirs to actually use it.