The fire environment of today is forcing a shift toward faster response and faster application of water to the seat of the fire.1 Numerous studies have shown that while temperatures in the fire environment may not be “hotter,” modern fuels are supporting fire growth with significantly less time between ignition and flashover because of high heat release rates.

There are any number of reasons a fire can grow, unchecked by water application. When this occurs, departments must have options available to combat fires that have exceeded the growth of a typical one- to two-bedroom residential fire. Rather than arguing when and when not to pull larger attack lines, we will assume that there is a time and place for them and focus on how a department can decide on which of the medium-diameter hoselines will best fit the needs of the department.

Attack hose was once 1½-inch or 2½-inch. We are no longer in the age of our grandfather’s fire service when it comes to purchasing fire hose; manufactures are providing options that run the gamut in terms of both performance and overall size. To just name a few of variations that are currently marketed as medium-diameter attack lines, you can purchase hose with an internal diameter of 2.05-, 2.10-, 2.25-, 2.3-, 2.5-, 2.75-, or 2.88-inch. Each of these hoselines is sold as the solution for heavy fire attack. With that being said, it is easy to see where confusion and clouded judgment can become prevalent. How do you sort through the process of deciding then?

While many fall into the trap of making purchase decisions strictly on the basis of cost, there should be significantly more to the process than dollars in and dollars out. This is not to say that departments should not value properly stewarding resources, but cost alone does not determine fireground performance. A proper hose study is recommended to anyone who is considering a change in fire hose purchasing. Many vendors and manufacturers are assisting in the testing process for little or no cost to departments that are unsure of what to look for in these tests. There is nothing inherently wrong with inviting a manufacturer to join in the discovery process; however, a sampling of products from a variety of sources will always provide the best view of what hose type will best fit the needs of the department.

1 Each of the four lines pictured range in size between 2.10 and 2.88. While visually this may not be obvious, their individual characteristics will cause notable variances in fireground operations. (Photos by author.)

2 Prior to purchasing hoselines of any size, complete thorough testing. This will confirm that the product will operate as intended, specific to the jurisdiction making the purchase. Once the product is delivered, hands-on training of department members affected by the purchase will confirm the intent of its usage and help clarify the decisions that led to the product selection.

The goal of any attack hose purchase should be to provide the department with a quality hose that improves the effectiveness of the companies that will be using it. This starts with asking, “Is this a manageable attack system?” The term “manageable” can be defined and quantified in several ways. Factors affecting the manageability of a handline include the fire stream volume, the velocity at which the water is moving, the reaction forces imposed through nozzle selection, the internal diameter of the hoseline, the overall construction of the hoseline, and its ability to resist kinks.

In its simplest form, however, I would expect a manageable hoseline to perform in such a manner that neither limits the nozzle firefighter to a single grip position on the hose nor the fire attack team, as a whole, in their full scope of water application methods. Then, you can consider each of these factors against the response area and tactical best practices to determine which hose option best fits your jurisdiction. Departments must explore these aspects with the knowledge that they are all interrelated. Decision making in a vacuum will lead to an attack package that, at best, carries inefficiencies and, at worst, can be catastrophic.

Determining a desired flow rate is a vital step in the process. Ideally, that flow rate for a large handline should not go below 230 gallons per minute (gpm) or above 300 gpm. Falling below the threshold creates a situation better suited for a 1¾-inch handline, and exceeding the threshold becomes an overwhelming task for most of the fire service. We are seeing the introduction of newer hose sizes specifically because of the value that has been proven in matching the internal diameter of hoselines to a desired flow range. Much of our current knowledge in matching flow rates to hose diameter is based on the works of renowned civil and hydraulic engineer John Ripley Freeman. He is credited with the “Freeman Ratio,” which states that the ideal nozzle tip size is one in which the internal diameter of the tip is at or less than one-half the internal diameter of the hoseline to which it is attached.2

For example, according to Freeman, a 2-inch hoseline is best paired with a 1-inch nozzle tip. It’s important to note the principle can roughly be applied to combination nozzles with flow rates and tip pressures similar to their smooth bore counterparts. By adhering to this principle, water will flow at a desirable velocity through the hose, create enough backpressure to reduce the potential for kinks and a “floppy” hoseline, and exit the nozzle with sufficient force to penetrate superheated environments. Therefore, a 30- to 40-gpm shift in desired target flow can create a situation where one hoseline diameter may be better suited than another.

Target Flow Selection

First, it is not appropriate to arbitrarily select a flow rate without first considering the forces acting on the nozzle team. The upper limits of target flow should be determined by the nozzle firefighter’s ability to counter nozzle reaction. This is a simple lesson in physics that states that force will act on the nozzle equally and in the opposite direction of the water exiting that nozzle. In essence, the greater the flow rate and the greater the pressure at the nozzle tip, the more nozzle reaction the firefighter will experience. You cannot just place a large nozzle tip on a small handline and expect the change in hoseline size alone to reduce the efforts required to combat reaction forces.

Much study has been done to determine how much force is acceptable to safely operate and manipulate an attack line by individuals including Andy Fredericks, Paul Grimwood, and Dave Fornell. Andy Fredericks concluded that about 70 pounds of nozzle reaction was the working limit of a single firefighter.3 Each of these parties would agree that having additional personnel assist in absorbing the reaction forces resulted in the ability to increase that working limit—however, not exponentially. Paul Grimwood felt that three firefighters had a working limit of around 100 pounds of force.4 It can then be presumed that reducing the pressure requirements at the nozzle tip will allow for a higher flow rate to be used.

Attack teams must be able to confidently flow water above, below, beside, and ideally behind them at a moment’s notice with a fully opened nozzle. This is achieved through a conscious effort to provide a hose and nozzle system that is paired for performance and is trained on heavily. Flow rates should be decided by considering the average abilities of department members; giving too much weight to abilities of the overachieving or underachieving members will result in a tainted perspective. Our profession is one that often tests the limits of human potential. These recommendations can always be exceeded, though rarely without consequence.

Flow rate is heavily dependent on the structure on fire and the total fuel involvement. Sole reliance on the flow rates typical of a residential fire attack will only leave an engine company grossly outgunned when the volume of fire exceeds that of what is common in two or three bedrooms or a single large residential room. National Fire Protection Association (NFPA) 1710, Standard for the Organization and Deployment of Fire Suppression Operations, Emergency Medical Operations, and Special Operations to the Public by Career Fire Departments, is often quoted as the reasoning for flows at or above 150 gpm from the first two handlines. This is absolutely acceptable for smaller handlines; however, exploring NFPA 1710 a little further reveals the suggested minimum flow increases to 500 gpm from the first several handlines on occupancies such as strip centers, commercial stores, and high-rise buildings.5

Pulling four handlines to achieve the suggested minimum flow rate is not only unnecessary, but it will never be accomplished in jurisdictions that are unable to bring sufficient staffing to an incident scene; rather, by selecting handlines with flow rates at or above 250 gpm, the standard is met with two operating handlines. The National Fire Academy and Iowa State University have each provided simple calculations to determine the amount of water necessary on a fire scene. Both are great reference points, but by taking a broader look at a department’s response district and the occupancies it has, plans can be made for potential flow requirements long before they are needed.

Staffing the Line

A common misconception is that it will always require multiple companies to successfully operate a medium-diameter hoseline in an offensive manner. Truth be told, a single firefighter can deploy a dry, large attack handline upward of 200 feet, then operate the nozzle without assistance when proper equipment has been purchased and proper training is provided. This is not an endorsement for a single firefighter to attempt an interior fire attack alone. Rather, it is stated to highlight the numerous situations where an understaffed fireground can be affected rapidly and positively by one engine company while awaiting the arrival of additional crews. It is preferable to maintain a minimum of three members on a large handline to mount an interior attack because of the additional weight and size of the line when compared to 1½-inch or 1¾-inch attack lines.

The line becomes significantly more mobile with each additional member placed on the line, and the goal should always be to properly staff hoselines operating in an immediately dangerous to life or health environment. With that being said, some jurisdictions will face limited staffing daily. In these situations, it may be beneficial to select hoselines with an internal diameter below 2½-inch and ideal target flows in the 230- to 265-gpm range to keep the overall weight of the attack package down and nozzle reactions manageable for effective fire attacks in short-staffed situations.

Conversely, departments that can consistently staff their hoselines with multiple members and companies can consider a 2½-inch hose and a target flow that reaches toward the 300-gpm threshold previously mentioned. In the end, however, the guiding principle is the size of the fire will always determine the flow rates necessary and not the staffing levels of the responding department.

Other Considerations

The overall weight of the hoseline dramatically impacts the ease in which a company can maneuver the line around a fireground. Friction points, tight hallways, and general clutter will all increase the work required to get that line into an operable position. The dry weight of a hoseline is often well advertised. Although this may play into the decision-making process, that weight can be deceiving. The additional dry material weight per foot added to some products often serves the purpose of assisting in the longevity of its use, resistance to thermal insults, and helping to prevent volume-stealing kinks.

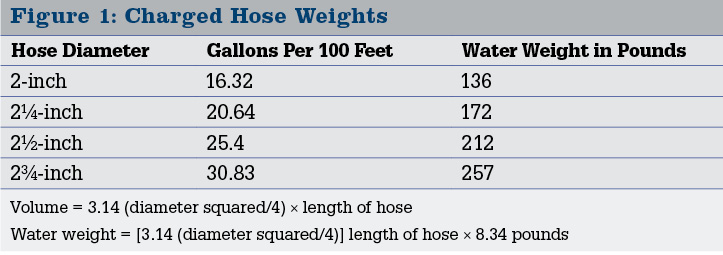

In many instances, the additional dry pounds are well worth the added benefits. Of far greater importance is the charged weight of the line. Water has a set weight of approximately 8.34 pounds per gallon. Therefore, by determining the internal diameter of a hoseline, you can identify just how much water weight an engine company is tasked with manipulating once water is sent down the line. Figure 1 breaks down the volume of water held in 100 feet of hose and the corresponding water weight to that volume.

3 If the decision is made to provide hose specific to a special operation, such as fire attack from a standpipe, bundling this hose and loading it on the apparatus separate from other hose sizes will speed up fireground decision making and allow companies to capitalize on the benefits of hose sizes their department has selected.

What the chart in Figure 1 highlights is how seemingly insignificant increases in hose diameters can ultimately cause the overall weight of the attack package to skyrocket. Since each of the four hose diameters listed can be purchased with 2½-inch couplings, it is common to see any one of them paired with an 11⁄8-inch smooth bore nozzle tip. Flow rate is a derivative of the size of the nozzle orifice and the pressure at which the water is delivered to the nozzle—not the diameter of the hoseline. Therefore, you can achieve the same 265 gpm flow rate on any one of these four hose sizes yet have more than a 100-pound variance in water weight in only 100 feet of hose. At this point, it should be clear that weight is just one of many factors to consider. If the charged weight was the only consideration, you could argue that the best practice would be to use the smallest diameter of hose that also meets the overall performance needs of the attack system.

The built environment to which a department responds has previously been mentioned in terms of flow rates; however, it deserves to be explored further. Early in my introduction to a hoseline with an internal diameter of 2¼-inch, I argued that it seemed to be a great fit for suburban fire departments, while urban departments should stick to 2½-inch hoselines. I was correctly chastised by a mentor that the argument had nothing to do with “suburban vs. urban firefighting” and everything to do with the buildings specific to each individual fire district. A “suburban” fire department can just as easily have structures common to a downtown high-rise district as an “urban” fire department that has adopted fire codes typically seen only in new construction.

When a department correctly chooses to incorporate building infrastructure into its method of handline attack package design, this brings about the need to address many additional factors in the creation of that system. One such example in a standpipe-equipped building is the pressure available at each hose valve outlet. The outlet becomes the crux of the hose options available to the company. The volume of water present in a standpipe is typically plentiful, while the pressure at which it is delivered is often limited. The age of the building and its standpipe system provide the biggest tell in what pressures are going to be available. NFPA 14, Standard for the Installation of Standpipe and Hose Systems, set the minimum outlet pressure at the most remote outlet valve to 65 psi in buildings constructed prior to the code revisions in 1993. Unfortunately, the minimum pressure allowed is often very near the maximum pressure provided, as the building contractor’s goal is only to meet the standard; rarely is it exceeded. The 65-psi standard was created with the assumption that fire crews would be using 2½-inch hoselines with stretches that did not exceed 150 feet. Unless a department can physically verify that outlet pressures in their buildings constructed prior to 1993 are greater than 65 psi, deploying a hoseline with a diameter any less than 2½-inch is a risky gamble.

After 1993, revisions to NFPA 14 increased the minimum outlet pressure to 100 psi.6 Although this was a positive change, it still does not allow an engine company to make their hoseline selections as if they were stretching from a rear hosebed. The increase came in part from some catastrophic events in standpipe-equipped buildings, namely One Meridian Plaza in Philadelphia, but more so because of the longer stretches companies were encountering after fire code changes allowed for travel distances of up to 200 feet between valve outlets in buildings with sprinklers.

Consider an example from my own response territory. A compilation of buildings creates a six-story mixed-use property with residential apartments over commercial storefronts. It has an overall footprint of roughly 400 feet × 400 feet and is aptly named “One City Block.” This style of construction is becoming common across the United States and lends to stretches that can easily exceed 300 feet, in some situations. This occurs when companies rightly make their hose connections on the floor below the fire and forgo the use of mid-hallway hose valve outlets that are useful only to meet NFPA requirements and post-fire operations.

Therefore, while residential compartmentalization may not necessitate the use of 2½-inch hoseline flow rates, there is a possibility that buildings will require the friction loss benefits of 2½-inch hose. Also of note, not all jurisdictions adopt code changes immediately following their being updated; a building constructed after the 1993 revisions may still be adhering to older code requirements if the authority having jurisdiction allowed this to occur. It is up to each individual fire department to get out into its response areas and determine ahead of time what size hoselines will be compatible with the standpipe infrastructure.

Let us imagine a jurisdiction that is understaffed and does not have buildings equipped with standpipes; all hose stretches are made from an engine hosebed. This sounds like the perfect opportunity to explore hoseline diameters less than 2½-inch. It is undeniable that mobility is gained, even within small reductions in hose sizes. With recent improvements in hose construction and flow rate capabilities on par with their larger counterparts, intermediary handline hose sizes have the potential to markedly improve fireground operations.

We cannot get something for nothing though, and the addition of mobility is countered with a greater amount of friction loss. This impacts long stretches and defensive operations. The testing of one manufacturer’s 2¼-inch hoseline has shown that the average friction loss in 100 feet of hose is about 20 psi while flowing around 250 gpm. This is an acceptable amount of pressure loss and will not limit travel distances, so long as the hose is operated within its intended purpose. On the other hand, if that same hoseline was used to supply a portable monitor, flowing in excess of 500 gpm, there is nearly 80 psi loss in the same 100 feet as mentioned above. The pressures required to maintain the desired 500-gpm flow rate, common to a portable monitor operation, will only allow crews to safely operate a short distance from their engine. In fact, a 3-inch supply line is often better suited to support 400- to 600-gpm flows from a portable monitor as even 2½-inch to 2¾-inch handlines do not fare much better than their smaller counterparts in tolerance for longer deployments from an apparatus and the overall system pressure requirements.

What is the Solution?

Having a variety of hoseline sizes available to meet the array of challenges an engine company will face is one solution to the problem of having so many possible fireground scenarios. This system only works when companies understand the intent and limitations of each hoseline and recognize the situations where they provide the greatest benefit. The feasibility of the practice can be limited within departments that lack formal training and are neither capable of providing the funding nor do they have the space on their apparatus. Providing a multitude of options can certainly beget confusion. The last thing we desire from company officers is for them to arrive on the scene of a working fire only to get caught in the quicksand of indecisiveness trying to figure out whether 2¼-inch, 2.3-inch, or 2½-inch is best. We want rapid, simple decision making from these individuals.

The route to achieving the balance between too little and too much is clarified through a firm grasp on the critical components of these large handlines and applying them in a manner that attempts to limit the potential for human error. Often, attainment of this goal is realized by limiting the department to only two sizes of attack lines for deployments from an apparatus. A small attack line with a target flow between 160 and 185 gpm with an internal diameter between 1.7-inch and 1.88-inch should be complemented with a large handline with flows between 230 and 300 gpm and an internal diameter between 2.2-inch and 2.6-inch. One additional size of line can be considered for special operations, such as standpipe operations. This should be bundled and loaded separately from traditional hosebeds. In doing so, the human factor leading to failures will be limited through targeted training and familiarization with a select few lines. When the company is task saturated and under high stress, decision making can then match the time-compressed scenario that a good working fire brings.

Therefore, a holistic approach to large handline package design should be the goal of every fire department when purchasing hoselines. It’s not for a vendor, neighboring jurisdiction, or even me to tell you where that happy medium is. Sometimes, the built environment itself may be demanding which hoseline size is required. It is on the individual fire department to step outside the firehouse office, explore its jurisdiction, and go flow water with the crews. That is how decisions are made.

Endnotes:

1. Zevotek, R., Stakes, K., & Willi, J. (2018). Impact of Fire Attack Utilizing Interior and Exterior Streams on Firefighter Safety and Occupant Survival: Full Scale Experiments (Rep.). Columbia, MD: UL FSRI.

2. Freeman, J. R. (1889). Fire Stream Tables for Use of the Inspectors of the Associated Factory Mutual Insurance Companies.

3. Fredericks, A. A. (2000, March). “Little Drops of Water: 50 Years Later, Part 2.” Fire Engineering.

4. Grimwood, P. (2006, September). “Firefighting Nozzle Reaction.” Retrieved from www.firetactic.com.

5. NFPA 1710, Standard for the Organization and Deployment of Fire Suppression Operations, Emergency Medical Operations, and Special Operations to the Public by Career Fire Departments. (2020). Quincy, MA: National Fire Protection Association.

6. NFPA 14, Standard for the Installation of Standpipe and Hose Systems. (2019). Quincy, MA: National Fire Protection Association.

Jonathan Brumley is a firefighter with the Denver (CO) Fire Department. He began his fire service career in 2009 and has served as a career and volunteer firefighter. Brumley has a BBA in finance along with numerous fire service certifications. He is an instructor with Fire by Trade, LLC., has taught at fire conferences nationally, and has previously been published in Fire Engineering.