By Chris Mc Loone

It is always amazing to see the new technology available to the general public in their personal vehicles.

Vehicles drive themselves, stop themselves, are connected to the Internet, and are trackable in the event of a theft. Thirty years ago, though conceivable, these options seemed a long way off. Yet, here we are. It is very conceivable then that some features available to the general automotive market would be available to fire apparatus customers. No, we’re not quite at the stage yet where a fire apparatus will drive you and your crew to the scene of an incident itself. But, we do have fire trucks that will slow themselves if an object is detected in front of them, and we’ve had electronic stability control for some time.

In recent years, fire apparatus cabs have become more modern, and the rigs themselves have gotten “smarter” by virtue of a variety of electronic controls. Pump panels have been shortened by using electronic valves, and sometimes consolidating all the information we’re accustomed to receiving – pump intake and discharge pressures, handline pressures, deck gun pressures – into a single touch screen at the pump panel, eliminating the analog gauges traditionally found on fire apparatus. Returning to the cab, more and more vehicle controls are performed at the touch of a button. As technology has evolved, so has how information is presented and what information can be presented.

There is now a cab console that can be as customized as the rest of the apparatus it controls. It was introduced at FDIC International 2017, features integrated touch-screen controls, and is offered by HME Ahrens-Fox.

Development

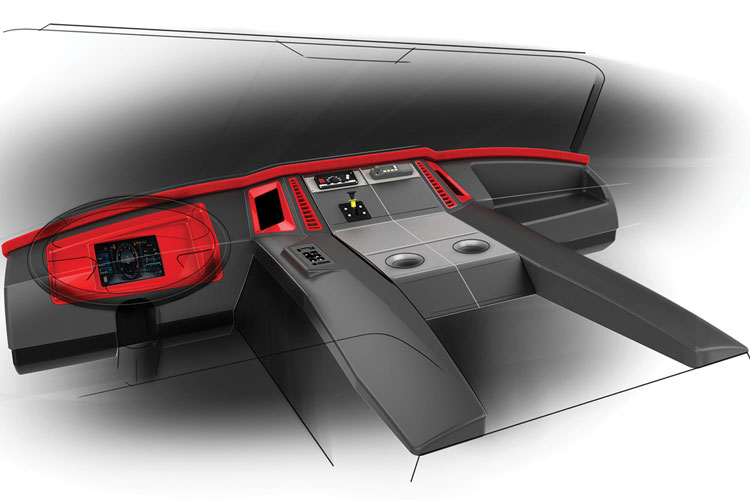

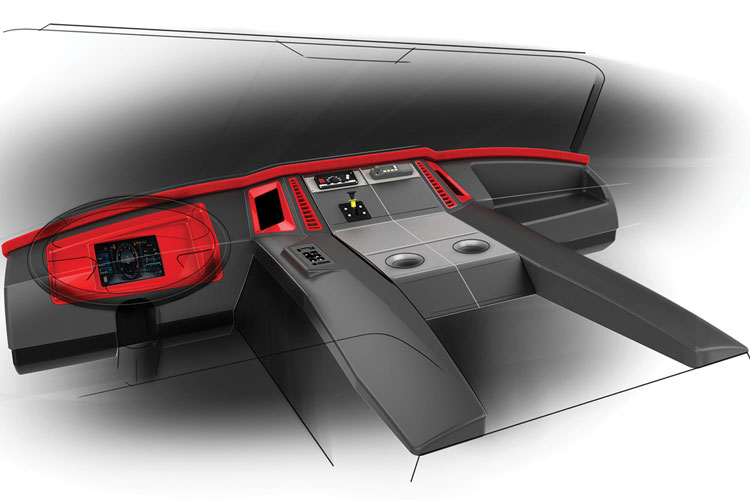

The innovation is called the “Glass Cockpit.” The sweeping arc of the front console provides essential truck instrumentation for the driver in an accessible and easy-to-read format. The driver’s console also features a right-hand panel with additional touch-screen switch controls. The officer’s side of the console features a left-hand touch-screen panel. Both panels feature adaptive touch-screen technology that can be configured to support individual apparatus command and control demands, as required. “When you take a look at the automotive industry, it has gone to a lot of liquid crystal displays and LED displays in vehicles,” says Ken Lenz, vice president, director of engineering, at HME Ahrens-Fox. “And, it gives them a host of customized options that they can provide to the user where they can go through screens, make changes to different things, and put those custom items in various menus. That’s what we’re looking at: having the ability to develop custom solutions for customers that are going to be very cost-effective because software is where we have the customization; the hardware is always the same. So, instead of having to buy an exhaust gas temperature gauge and then have wires that run it go into the dashboard and then make a knee dash panel to mount it, we could simply give it a screen, put a sensor on the data bus, and we’re done.”

Developing a product like this takes time and isn’t an overnight process, but HME was already slightly ahead of the curve. “The development actually started with our aerial products,” Lenz says. “The aerial was about two years ago, and it came out exclusively with a glass screen. So, we’re really adapting knowledge that we gained with the aerial device into the cab.” Lenz adds that the technology is already in the aerial platform and turntable, and he expects it to be available at the pump panel in early 2018.

“The new cab console design complements the development of our own, proprietary touch-screen command and control technologies,” he says. “The cab console module will be incorporated throughout our custom fire apparatus line, as well as in evolving HME Ahrens-Fox cab designs. The module offers command and control in a modular, ergonomic layout that quite literally puts apparatus controls at the driver and officer’s fingertips.”

|

| 1 The sweeping arc of the front console provides essential truck instrumentation for the driver in an accessible and easy-to-read format. The driver’s console also features a right-hand panel with additional touch-screen switch controls. (Photo courtesy of HME Ahrens-Fox.) |

Flexibility

In the driver’s seat, the Glass Cockpit is beneath the steering wheel, so the dashboard is completely digital. But, there is more to it than just gauges. For example, when the driver puts the truck in reverse, the dashboard changes to the rear camera’s view. “We can put a backup camera in for the driver,” says Lenz. “Additionally, we can put the backup camera in for the officer on his screen so we can have two people watching what’s going on when the vehicles are backing up. Those cameras can also be placed anywhere around the truck. We can put a left camera or a right camera so that when they are changing lanes someone else can be watching.”

On the officer side of the vehicle, there is a host of information available. “One thing for certain is we can give the officer everything the driver has,” states Lenz. “We can mirror these screens. But, the officer is busy with other things, so he has a different agenda usually. In the normal screen, there is a compass setting, a temperature setting, and a speedometer. We give him all the engine functions. We also give him control over things like lighting. So, we’re giving him a lot more control of what’s going on in that response and yet not trying to overwhelm him. We can give him everything exactly like the driver has if that’s what the department wants.

As far as the instrumentation that the driver is used to seeing when operating the vehicle, it’s all there. “Anything on that truck that we would find pertinent to a driver we can put on that screen,” adds Lenz. “It’s a matter of making the screen mask, which is the graphics, and then putting it in the code to accept the data and make the numbers turn, the needles move, or whatever the case may be. We’re putting compasses in. We’re putting outside temperature in. With a little more sophistication, we can put GPS locations on a map in the screen. As we develop the Glass Cockpit, one of the other things that will come into play is a vehicle WiFi network where we can have vehicles showing on a map where they are located. We can even, as time goes on, put wireless controls in and control multiple vehicles with one control.”

The modular center section of the console can also be configured to support individual crew and department needs including storage of personal equipment and gear, cup holders, clipboards, communication devices, additional switches, power outlets, and information ports.

The flexibility doesn’t end with what’s currently available. Lenz says, “It opens the door to a wide host of things we can do. You can imagine having networked trucks at a fire scene where a firefighter is operating two trucks at one time. And yet, what we want to do is do that with the user still having an experience of operation similar to what he has today with the mechanical equipment. At FDIC, we had the switches that look like a switch and when you pressed it you had the lumen of a switch. We’re working with the screen so when you press the switch it will give you a click so it will seem like you just touched a switch. So, it opens up the door. If you can dream it, we can do it.”

The cab console is constructed of durable, wear-resistant materials to provide for easy maintenance and long service life and is offered in colors to match individual department specifications.

Communication

The glass panel screen communicates with devices via multiplexing. “So, if we are going to turn on and off a switch, it’s actually going out on the data bus and saying ‘this switch is on or off,’ ” explains Lenz. “And, somewhere in the network you now have a receiving end that says ‘I now have a signal to turn off,’ and it turns off the warning light. Without that, we’d lose the benefit because we’d have to run wires from all the screens to wherever we’re going on the truck. Now, we just have a twisted pair and it gets to the other end where the node decodes it and turns on or off the device.”

HME will soon introduce Generation 2 of the Glass Cockpit with more menu-driven screens that allow users to change the look and feel of how the information is presented. “It’s really building on the foundation that we had, adding screens and features to it,” Lenz says, adding that Generation 2 options should be available at the beginning of 2018.

Ultimately, the Glass Cockpit is part of the continuing evolution of what’s available via multiplexing. “With the multiplexing systems available in the market, they’ve had officer side information centers and controls for quite some time,” says Lenz. “Really what the Glass Cockpit has given us is the freedom of build to give the style that we want to give for whatever the customer’s needs are and not be confined with what is commercially available. It’s a continuing evolution.”

CHRIS Mc LOONE, senior editor of Fire Apparatus & Emergency Equipment, is a 24-year veteran of the fire service currently serving as a safety officer and former assistant chief with Weldon Fire Company (Glenside, PA). He has served on past apparatus and equipment purchasing committees. He has also held engineering officer positions, where he was responsible for apparatus maintenance and inspection. He has been a writer and an editor for more than 20 years.